Engineering

| Latest Innovations |

|---|

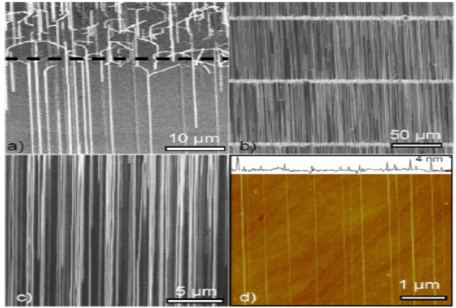

Carbon Nanotube Portfolio for Manufacturing ApplicationsThis portfolio includes carbon nanotube growth and processing methods relevant to nanotube manufacturing.... This portfolio includes carbon nanotube growth and processing methods relevant to nanotube manufacturing. Patterned Catalyst Techniques for Aligned Single-walled Carbon Nanotube GrowthSingle-walled carbon nanotubes (SWNTs) feature exceptional electric properties (conductivity and semi-conductivity) that make them attractive for nano-electronics, optics, material applications and more. This SWNT growth technology yields a dense structure without degraded alignment by eliminating undesired interactions between the SWNT and catalysts on the growth surface. More specifically, a patterned catalyst is used to provide a template to direct SWNT growth, resulting in perfectly aligned high coverage SWNTS. Benefits

Applications

Medium Scale Carbon Nanotube Thin Film Integrated Circuits on Flexible Plastic SubstratesThis technology improves the performance and consistency of integrated circuits featuring semi-conductive carbon nanotube (CNT) transistors. Specifically, metallic conductive pathways in random nanotube networks are reduced using a medium scale carbon nanotube thin film. This process reduces these pathways by cutting fine lines into the carbon nanotube network while preserving its semiconducting properties. Benefits

Applications

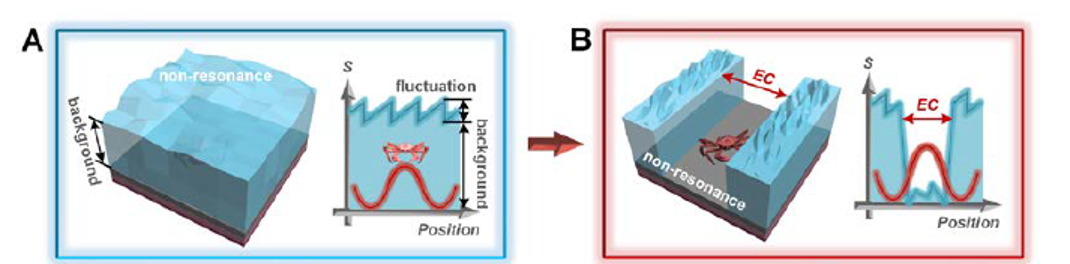

Using Nanoscale Thermocapillary Flows to Create Arrays of Purely Semiconducting Single-Walled Carbon NanotubesThis carbon nanotube (CNT) purification technology facilitates scalable, damage-free separation of arrayed metallic and semi-conductive CNTs. Resulting CNT arrays may be large and feature high Ion/Ioff ratios, allowing for less power loss while powered off, faster switching times, and overall lower operating voltage. The invention improves CNT array quality by creating a temperature gradient to release metallic CNTs from the array matrix. Benefits

|

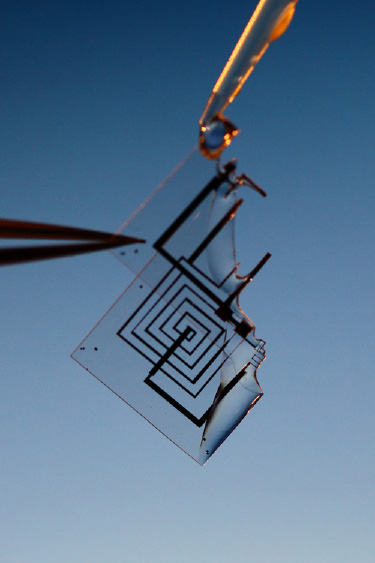

Suite of Bioresorbable and Transient Electronics

Transient electronic devices belong to a set of technologies, whereby traditional analog electronic circuits and components have been made in new ways. These new electronics exist on a much smaller scale and made of bioinert or biocompatible materials. They are flexible and transient. Transient and bioresorbable technologies are a class of device that have the ability to physically disappear at a programmed rate. Inventions within this suite includedevices and processes with applications rangingfrom medicine to construction, and from defense/securityto indoor/outdoor sensors. These technologies are appropriate for applications where device placement can be costly, invasive, or inconvenient to retrieve. Features

Benefits Electronics can now be implanted on surfaces with non-planar contact patches and non-invasive integration on soft, curvilinear surfaces of biological tissues and organs. Application Areas Remaking electronics with these capabilities permits for a plethora of new applications, in medicine, environmental research, biological enhancement, digital financial transactions and traceless surveillance.

|

|

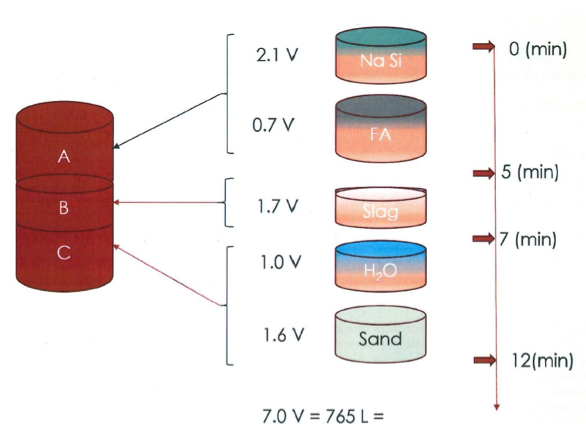

Self-Compacting Geopolymer ConcretesThis geopolymer was developed through a collaboration between Professor Waltraud Kriven at the University of Illinois and the Construction Engineering Research Laboratory... This geopolymer was developed through a collaboration between Professor Waltraud Kriven at the University of Illinois and the Construction Engineering Research Laboratory (an entity of the U.S. Army Corps of Engineers). The concrete alternative is made from a geopolymer-based flowable binder, the supplementary cementitious materials fly ash and blast-furnace slag, alkali metal silicate, and added water. Fly ash is a byproduct of coal combustion, while slag is a byproduct of steel manufacturing. Repurposing fly ash and slag, which are considered raw waste materials, reduce emissions of CO2 by reducing the proportion of clinker produced in the Portland cement manufacturing process. Use of fly ash and blast-furnace slag in this concrete alternative is environmentally friendly and enhances the performance of key concrete properties including strength, set time, and workability. The geopolymer concrete mixture is ideal for applications requiring a short set time and high strength development, including roadway repair and general construction within warmer climates. This invention is patent pending (application number 16/255,131).

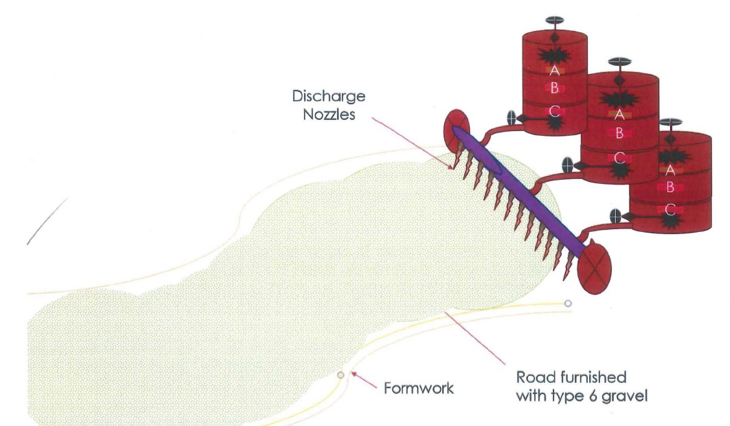

The flowable geopolymer binder may be deployed and mixed in a drum for increased flexibility in a range of applications.

The flowable mortar is distributed over a bed of coarse aggregate, curing rapidly to create a stronger, more environmentally-friendly concrete alternative.

|

|

|

|

|

|

|

Bio-compatible

Bio-compatible