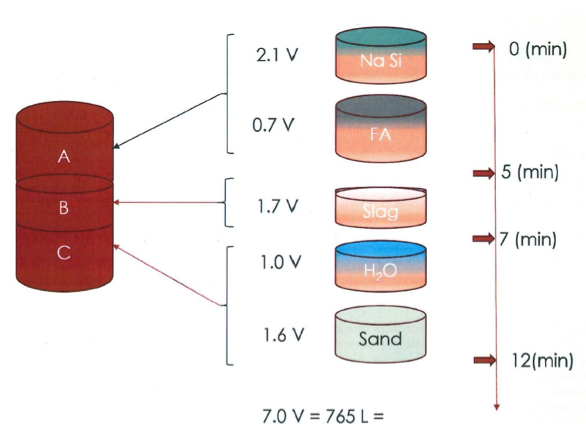

This geopolymer was developed through a collaboration between Professor Waltraud Kriven at the University of Illinois and the Construction Engineering Research Laboratory (an entity of the U.S. Army Corps of Engineers). The concrete alternative is made from a geopolymer-based flowable binder, the supplementary cementitious materials fly ash and blast-furnace slag, alkali metal silicate, and added water.

Fly ash is a byproduct of coal combustion, while slag is a byproduct of steel manufacturing. Repurposing fly ash and slag, which are considered raw waste materials, reduce emissions of CO2 by reducing the proportion of clinker produced in the Portland cement manufacturing process. Use of fly ash and blast-furnace slag in this concrete alternative is environmentally friendly and enhances the performance of key concrete properties including strength, set time, and workability.

The geopolymer concrete mixture is ideal for applications requiring a short set time and high strength development, including roadway repair and general construction within warmer climates. This invention is patent pending (application number 16/255,131).

The flowable geopolymer binder may be deployed and mixed in a drum for increased flexibility in a range of applications.

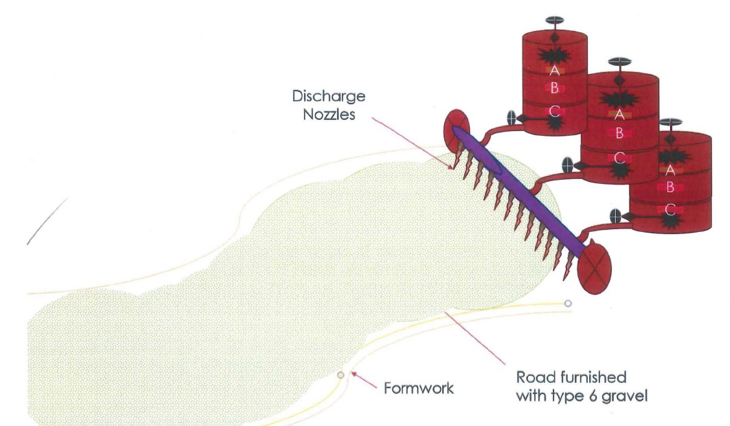

The flowable mortar is distributed over a bed of coarse aggregate, curing rapidly to create a stronger, more environmentally-friendly concrete alternative.