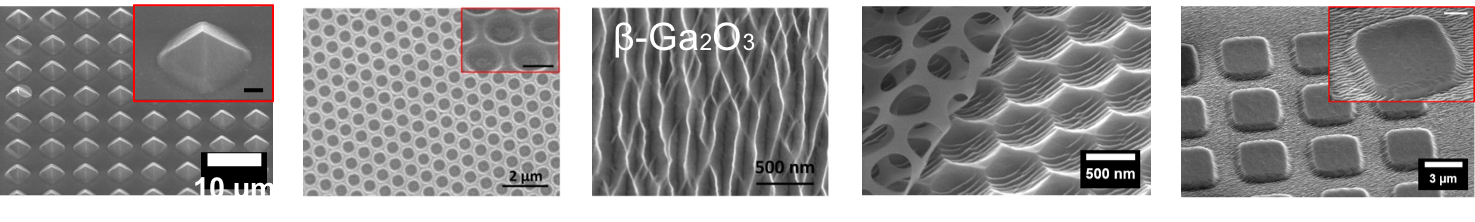

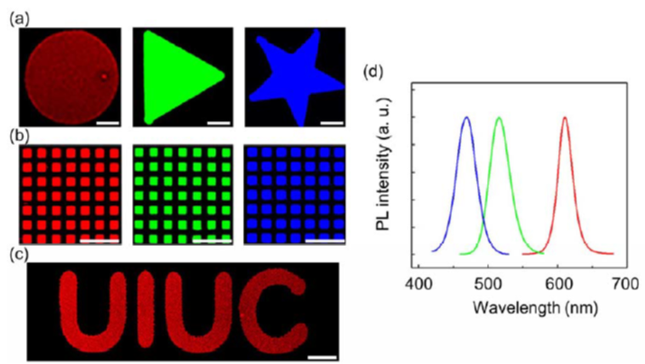

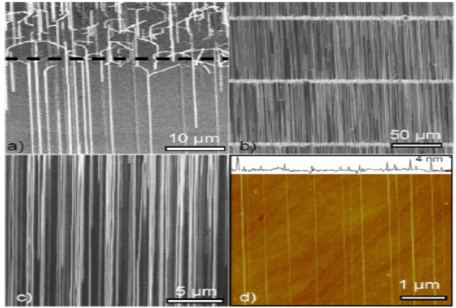

The invention is a novel method for manufacturing porous semiconductors, including silicon (Si), gallium nitride (GaN) and silicon carbide (SiC). The method... The invention is a novel method for manufacturing porous semiconductors, including silicon (Si), gallium nitride (GaN) and silicon carbide (SiC). The method involves applying a thin, discontinuous metallic (preferably platinum) layer to a semiconductor wafer, prior to using common wet chemical etchants (e.g., hydrogen fluoride, hydrogen peroxide), to produce porous silicon (PSi) or other porous semiconductors (PGaN, PSiC). DetailsPorous semiconductors are of interest for their novel optical, electronic, and chemical properties, with PSi being of particular interest. This technology applies a thin, discontinuous layer of metal to a semiconductor wafer before using a wet chemical etching process to produce a controlled thickness of porous semiconductor. The process can be adjusted to produce specific morphologies and desired light emission spectral and/or spatial distributions. How it WorksThis technology introduces a thin, metal catalyst film (a few nanometers in thickness) onto the semiconductor wafer surface, prior to immersion in an aqueous, oxidizing solution of hydrofluoric acid and hydrogen peroxide (i.e., H2O2 metal-HF etching). This process results in the simple and effective production of porous semiconductor. The simplicity and patterning capability will enable large-scale production. PSi with various morphologies, etch depths, and luminescent properties can be produced by adjusting the type(s) of metal layer deposited (gold, platinum, or gold/palladium) as well as the dopant type and level (p+, p-, or n+) of the silicon. Why It Is BetterCurrent methods for generating PSi use anodic etching. In anodic etching, a silicon wafer with attached electrodes and leads is submerged in a wet chemical bath and an electrical bias is applied to drive the etching process. While PSi is not commonly used today in optical or electrical devices, anodic etching is used routinely to generate PSi used to fabricate silicon-on-insulator (SOI) wafers for the electronics industry. A drawback of anodic etching is the extra infrastructure and complexity of applying an electrical bias to a thin wafer submerged in an etchant. At a minimum, it requires electrodes, leads, a power supply, and control electronics. This new technology is an elegantly simple alternative to anodic etching. It is an electroless technique, i.e., external electrical bias is not required, that circumvents all electrical accessories and associated methods. This novel process is also robust, controllable, and even allows flexibility for generating PSi in selected areas rather than across the entire wafer. In addition, this technology provides up to an order of magnitude enhancement in the luminescent properties of PSi compared to those of material produced using anodic etching. Furthermore, researchers may find applications for PSi that would never be possible using anodic etching. ApplicationsPSi could be used in the following emerging applications: - Light-emitting diodes (LEDs)

- Chemical/Biological sensors

- Compliant substrates for heteroepitaxial growth (e.g., nitrides)

- Sacrificial layers for microelectromechanical devices Low-dielectric interconnects

Benefits- Enhanced Control over Product Properties: Both the morphology and light-emitting properties (spatial profile, wavelength) of the semiconductor can be tailored as a function of metal deposited, semiconductor doping level, semi-doping type, and etch time.

- Simple and Robust Process: By using metal deposition and etching, both simple, accepted processes in microelectronics, this "contactless" technology does not require the presence of electrical contacts or other stimuli/equipment to control etching.

- Directed Area Etching/Luminescence: Selective deposition or patterning of the metal catalyst allows controlled creation of etch variations in substrates below and adjacent to the metal. This method can also create selected areas with unique emission properties.

- Promising Potential Properties: This technology might lead to in situ contacts for porous semiconductors/silicon; have potential for ten-fold better luminescent emission from PSi than that obtained from anodic etching; enhance the emission of other semiconductors beyond silicon (e.g., GaN) or enable compliant substrates for heteroepitaxy; and enable creation of PSi on a variety of substrate shapes and sizes.

|

Distributed Bragg Reflectors (DBRs) are a fundamental component of optical devices requiring an optical gain, such as various types of semiconductor lasers.... Distributed Bragg Reflectors (DBRs) are a fundamental component of optical devices requiring an optical gain, such as various types of semiconductor lasers. Conventional methods of forming DBRs require high numbers of layers of semiconductor materials to get the desired reflective resolution. This new method of forming DBRs controls the microstructure of the layers and offers improved vertical cavity surface emitting lasers (VCSELs) and resonant cavity light emitting diodes (LEDs). This technology is a method for making a highly reflective interface for distributed Bragg reflectors (DBRs), which are used in VCSELs and resonant cavity LEDs to generate optical activity. Using Group III-V materials, the interface consists of amorphous layers that contain aluminum, which when oxidized significantly increases the refractive index. As a result, the number of layers needed for the DBR can be reduced from about 30 to 4 or 5. A key element of this technology is that by using a combination of alternating polycrystalline and amorphous materials the layers can be applied to any surface, regardless of the substrate's lattice constant. Therefore, the DBR can be created on any substrate, including glass and silicon, and has a wider range of design possibilities. Additionally, changing the thickness of the layers allows reflectors of different wavelengths to be created. Highly reflective DBRs which reflect in the short wavelength of the visible spectrum and deep into the ultraviolet wavelength can be formed by this method. This technology has been tested extensively with the most common material sets, gallium arsenide (GaAs) and gallium phosphide (GaP) systems. Benefits- Enables fabrication on any surface, even silicon, widening the range of useful materials and designs.

- Decreased processing due to reduced number of layers Increased options for substrate material, including silicon, glass, and other low-cost options.

- Increased design options, particularly when integrating into electronics and optical devices Improved tolerance of temperature variation due to the DBRs more stable characteristics

|

The technology is a chemical method for preparing ultrathin oxide films on silicon with low leakage currents and high capacitance, optimizing the electrical... The technology is a chemical method for preparing ultrathin oxide films on silicon with low leakage currents and high capacitance, optimizing the electrical properties of the dielectric barrier. DetailsAn alternative gate dielectric material will be required for scaling of microelectronic devices to continue at its present rate. The decreasing dimensions of the transistor have required thinner and thinner gate oxide films to maintain capacitance. Unfortunately, leakage currents through silicon dioxide film become too high when using films thinner than 2 nm. Alternative gate oxide materials with a higher dielectric constant have been sought, but the problem has been finding a material which will not form an interfacial layer of silicon dioxide between the high-k dielectric and silicon substrate, and can be deposited using an economically viable process. Continuous dielectric films for silicon based electronics of thicknesses far less than is possible with SiO2have been demonstrated, with high chemical purity and exceedingly low leakage current. This is accomplished through repeated condensation-hydrolysis reactions using n-propyl orthozirconate. The resulting materials will permit the best FET gate material, and when combined with other innovations, the lowest power, highest speed transistors possible. ApplicationsThe primary application for this technology is for integrated circuits; processors and memory applications are the main applications for IC (integrated circuit) technology. Examples of such applications include: - Semiconductors

- Microelectronics fabrication

- Electronic chemical industries

- Tool manufacturing

Other applications would include sealing or passivation of silicon surfaces in electronics and capacitors on chips. Benefits- Smaller, Faster, & More Efficient: High dielectric constant material allows for continuation of size reduction and increased area density

- Increased purity: Key to this technology is the purity of the zirconium Industry potential: High dielectric constant material with low leakage currents

|

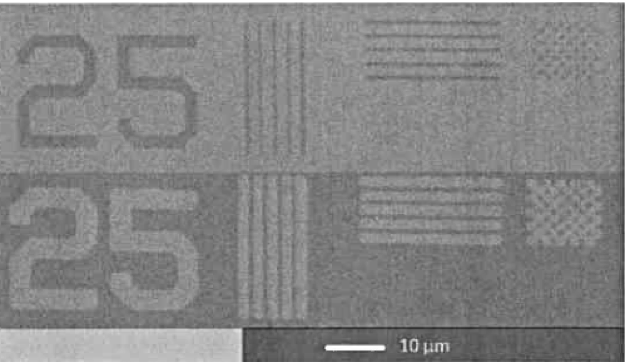

Developed by the University of Illinois at Urbana-Champaign, this suite of six technologies enhances multiple facets of nanolithography and scanning probe... Developed by the University of Illinois at Urbana-Champaign, this suite of six technologies enhances multiple facets of nanolithography and scanning probe microscopy. The suite features multifunctional, active probe arrays that enable nanoscale and microscale printing with multiple fluids, nanotube micromachining techniques for high-resolution probe tips, fluid dispensing systems for multiple probes, and a simple electrostatic actuation method for independently lifting individual probes in a high-density probe array. Used singularly or combined, the technologies each offer unique qualities and benefits that simplify and enhance both nanolithography and scanning probe microscopy. ApplicationsThe methods and materials that these technologies utilize can be applied to all types of scanning probe nanolithography as well as scanning probe microscopy. Applications include: - Biotechnology: High-density microarrays or biochips for genomics, toxicology, proteomics, and biological and chemical sensing.

- Semiconductors: Microelectronic components, photomask repair, and direct-write nanolithography.

- Imaging: High throughout scanning probe microscopy, mapping surface characteristics, and detecting surface defects.

BenefitsUsing essentially the same equipment but with varying probes and software, Scanning Probe Microscopy (SPM) with nanoscale probes offers great potential for both nanolithography and imaging. The Nanotip Engineering Suite enhances the functionality of SPM equipment, offering benefits in applications ranging from bioscience to semiconductors. Miniaturization of semiconductor chips could be greatly advanced with the use of scanning probe nanolithography. In genomics and proteomics, biochips containing arrays of dots such as DNA fragments allow researchers to study the vast number of interactions of various proteins on a single chip. Like semiconductor chips, the development of nanoscale scanning probes has great potential benefits for the creation and study of biochips. Current scanning probe nanolithography techniques for creating high-resolution patterning have limitations in both resolution and complexity, and they use inefficient processes. The Nanotip Engineering Suite eliminates many of those limitations and improves the overall process for nanolithography as well as scanning probe microscopy. 1. Multifunctional Probe Array (TF04157)Most current scanning probe lithography methods use a single tip or tip array that must be changed if a second "ink" needs to be applied. This probe change also requires calibration in order to maintain alignment and accuracy. Ths step is both time-consuming and inefficient and also often introduces contamination. To address these issues, this technology provides a multifunctional probe array with active probes that can perform direct chemical patterningand imaging sequentially in a singlerun with accurate registration and no need for changing probes. The technology uses actuators to enable individual control of probes for up and down movement as needed. Patterns using different chemicals and ranging from nano- to microscale can be created and then imaged without risk of cross-contamination and while eliminating the inefficiencies of switching probe tips. Benefits- More versatile: An active multiprobe array enables the use of probe tips of differing sizes for generating patterns of differing sizes. Redundant probe tips can also carry different chemicals simultaneously for multi-ink lithography.

- Faster: This technology enables patterning and imaging sequentially in a single run, eliminating the need to change probes and recalibrate.

- Eliminates cross-contamination: By patterning and imaging with different probes within the same array, this technology eliminates the problem of cross-contamination.

- Accurate: Because the tip-to-tip distance in the array is known, accurate registration between patterns is easily achieved.

- Precision control: An integrated thermal actuator allows control to raise or lower individual probes.

2. Probe Fabrication Method and Microcontact Printing Technique (TF02082)Scanning probe microscopes perform measurements using a probe that has a flexible cantilever beam with a sharp tip attached at the distal end. The fabrication methods for these probes have a number of major drawbacks, including time- sensitive and inefficient processes and difficulty in producing uniform sharpness. Because the cantilevers are made of inorganic thin films, high temperatures and multi-step processes are required to produce them. This new method for probe fabrication and microcontact printing eliminates these problems, while producing either a single probe or an array of probes. It uses an efficient process, lowcost materials, and produces a uniform probe profile. This technology also includes a method for microcontact printing using the fabricated probes described above with integrated elastomeric tips and a commercial scanning probe microscope. This method eliminates the costly and timeconsuming need for a photolithography mask by attaching "inks" to the probe tip and creating patterns with connecting dots. This new technique combines the sub-micrometer accuracy and features of the SPM with the chemical versatility and performance advantages of microcontact printing. Benefits- Lower cost: By utilizing a substrate and sacrificial layer, probes can be fabricated at lower cost than with current fabrication methods. Additionally, the direct microcontact printing technique lowers costs by eliminating the need for a photolithographic mask.

- Improved efficiency: Reusing substrate templates to fabricate additional probes saves time as well as maintains consistent size and sharpness.

- Improved performance: Because the microcontact printing technique combines the features of the SPM with the chemical versatility and performance advantages of microcontact printing, sub-micrometer accuracy is enabled.

3. Machining Nanotube-sized Tips from Multiwalled Nanotubes (TF04162)This technology uses an electron beam machining process to sharpen boron nitride nanotubes into fine-tipped probes for use in atomic force microscopes for molecular and nanostructure imaging and surface manipulation. The nanotube probes are of high strength, high Young's modulus of elasticity, and provide high aspect ratios. Benefits- High strength: Because they are formed from multi-walled nanotubes, the resulting tips are very strong.

- High aspect ratio: The tip's fine point and nanometer-scale size enable high aspect ratios for viewing at the atomic level, providing a significant improvement.

4. Atomic force Microscopy (AFM) Fluid Dispensing System for Probe Arrays (TF02040)To meet the need for an arrayed fluid dispensing system for multiple probes, this technology provides fabrication methods for multiple micro-channels connected to an array of fluid wells. This technology allows side-by-side probes to receive individual inks to create high-density arrays, particularly beneficial for studying biochemical substances such as DNA or proteins. Benefits- Multiple Inks: Current technologies for inking nanolithography probes do not allow the placement of unique inks on each probe tip. Individual tip inking allows for application in high-density DNA and protein arrays.

5. Electrostatic Actuators for Controlling Vertical Movement of Probes(TF03110)Problems with existing electrostatic actuators include complex fabrication methods, low deflection and force generation, large footprints requiring much wafer space and widely spaced probe tips. This design and fabrication method for electrostatic actuators uses the substrate surface as an electrode, simplifying fabrication. It also results in greater deflection and force and a much smaller footprint, enabling ultrahigh density probe arrays with improved performance. Benefits- Simplified fabrication: Because this system includes only one electrode (in the probe), fabrication is greatly simplified.

- Smaller footprint: The electrostatic force and probe stiffness are linear functions of the probe width, making the actuation method highly scalable to very small sizes, potentially enabling ultra-high density probe arrays.

- Better performance: High voltage differences can be applied across the electrodes, resulting in high forces and large deflections.

|

A polymer comprises at least two types of monomer units selected from: (1) diethynyl benzene units, (2) triethynyl benzene units, and (3) ester units. After curing... A polymer comprises at least two types of monomer units selected from: (1) diethynyl benzene units, (2) triethynyl benzene units, and (3) ester units. After curing, the polymer may form a condensed polyaromatic dielectric having a dielectric constant of at most 2.0 at 1 MHz, an elastic modulus of at least 7.7 GPa, and a hardness of at least 2.0 GPa. |

This technology provides a technique for fabricating metallic structures with dimensions considerably smaller than 10 nm and the use of a focused electron beam to... This technology provides a technique for fabricating metallic structures with dimensions considerably smaller than 10 nm and the use of a focused electron beam to locally manipulate nanowires with a resolution of about 3 nm. This is the first technology to use an electron beam and achieve such a high resolution of matter manipulation. Metallic devices hold promise for miniaturization because the electronic wavelength is much smaller in metals than in semiconductors. This technology allows users to fabricate metallic structures with dimensions around 4 nm. The method is based on the application of single linear molecules. This type of metallic decoration results in a very thin metallic wire. Researchers have discovered that in order to produce continuous homogenous wires without breaks, one has to use amorphous metals and alloys which exhibit a high adhesion to the molecule. This technology also allows the use of a focused electron beam to locally modify the shape and the morphology of nanowires with a resolution of about 3 nm. A high energy focused electron beam is used for this purpose. The beam is available in a standard transmission electron microscope. Additionally, this technology can produce a nanograin small enough that its charging energy is less than room temperature thermal fluctuation energy. Therefore, these grains can act as room temperature, single-electron tunneling transistors. Also, pronounced quantum-size effects can occur at low temperatures. This technology could potentially lead to single-electron devices smaller than those attainable through conventional semiconductor technology or even to highly integrated quantum computers. Applications:- Miniaturization

- Quantum computers

- Nanowire crystallization, etching and melting

- Superconducting devices

- Single-electron devices

Benefits:Size - The ability to create metallic structures with such small dimensions can be used to improve numerous applications. |

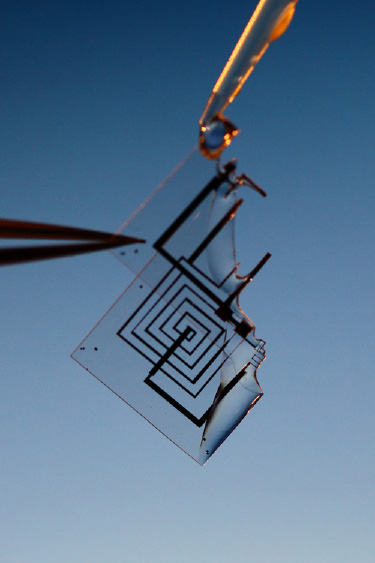

An innovative, cost-effective method for making and integrating fluidic microchannels. This method for ultra-rapid prototyping of microfluidic systems requiring... An innovative, cost-effective method for making and integrating fluidic microchannels. This method for ultra-rapid prototyping of microfluidic systems requiring fewer than 5 minutes from design to prototype uses liquid phase polymerization as an alternative to etching microchannels in silcone or glass. The method consists of introducing liquid prepolymer into a plastic or glass cartridge, exposing the prepolymer to ultraviolet light through a mask to encourage photopolymerization and define channel geometry, removing the unpolymerized prepolymer, and rinsing the resulting microchannel. ApplicationsThe actuators used in this technology require nothing more than the chemicals surrounding them to monitor the chemistry, mimicking chemical balances as they are maintained in the human body. This new method is ideal for biological and medical applications requiring organic materials, no electronics or batteries, bioresponsiveness, and a single, uniform platform for processing. Potential applications include detection of biological and chemical agents, disease, and contaminants, and in vitro diagnostics and therapy devices. Other promising applications exist in the area of microelectromechanical systems (MEMS). BenefitsThe invention greatly reduces the time and cost associated with the creation of microfluidics systems and requires no experience in microfabrication techniques, no cleanroom facilities, and no expensive equipment. Easy integration enables a manufacturing environment to readily incorporate "add-on" fluidics. This new technology allows ultra rapid prototyping and iterative design, affords immediate production of components, and simplifies complex systems |

The invention is a novel method for manufacturing porous semiconductors, including silicon (Si), gallium nitride (GaN) and silicon carbide (SiC). The method... The invention is a novel method for manufacturing porous semiconductors, including silicon (Si), gallium nitride (GaN) and silicon carbide (SiC). The method involves applying a thin, discontinuous metallic (preferably platinum) layer to a semiconductor wafer, prior to using common wet chemical etchants (e.g., hydrogen fluoride, hydrogen peroxide), to produce porous silicon (PSi) or other porous semiconductors (PGaN, PSiC). Porous semiconductors are of interest for their novel optical, electronic, and chemical properties, with PSi being of particular interest. This technology applies a thin, discontinuous layer of metal to a semiconductor wafer before using a wet chemical etching process to produce a controlled thickness of porous semiconductor. The process can be adjusted to produce specific morphologies and desired light emission spectral and/or spatial distributions. This technology introduces a thin, metal catalyst film (a few nanometers in thickness) onto the semiconductor wafer surface, prior to immersion in an aqueous, oxidizing solution of hydrofluoric acid and hydrogen peroxide (i.e., H2O2 metal-HF etching). This process results in the simple and effective production of porous semiconductor. The simplicity and patterning capability will enable large-scale production. PSi with various morphologies, etch depths, and luminescent properties can be produced by adjusting the type(s) of metal layer deposited (gold, platinum, or gold/palladium) as well as the dopant type and level (p+, p-, or n+) of the silicon. Current methods for generating PSi use anodic etching. In anodic etching, a silicon wafer with attached electrodes and leads is submerged in a wet chemical bath and an electrical bias is applied to drive the etching process. While PSi is not commonly used today in optical or electrical devices, anodic etching is used routinely to generate PSi used to fabricate silicon-on-insulator (SOI) wafers for the electronics industry. A drawback of anodic etching is the extra infrastructure and complexity of applying an electrical bias to a thin wafer submerged in an etchant. At a minimum, it requires electrodes, leads, a power supply, and control electronics. This new technology is an elegantly simple alternative to anodic etching. It is an electroless technique, i.e., external electrical bias is not required, that circumvents all electrical accessories and associated methods. This novel process is also robust, controllable, and even allows flexibility for generating PSi in selected areas rather than across the entire wafer. In addition, this technology provides up to an order of magnitude enhancement in the luminescent properties of PSi compared to those of material produced using anodic etching. Furthermore, researchers may find applications for PSi that would never be possible using anodic etching. Applications:- Light-emitting diodes (LEDs)

- Chemical/Biological sensors

- Compliant substrates for heteroepitaxial growth (e.g., nitrides)

- Sacrificial layers for microelectromechanical devices

- Low-dielectric interconnects

Benefits:- Enhanced Control over Product Properties: Both the morphology and light-emitting properties (spatial profile, wavelength) of the semiconductor can be tailored as a function of metal deposited, semiconductor doping level, semi-doping type, and etch time.

- Simple and Robust Process: By using metal deposition and etching, both simple, accepted processes in microelectronics, this "contactless" technology does not require the presence of electrical contacts or other stimuli/equipment to control etching.

- Directed Area Etching/Luminescence: Selective deposition or patterning of the metal catalyst allows controlled creation of etch variations in substrates below and adjacent to the metal. This method can also create selected areas with unique emission properties.

- Promising Potential Properties: This technology might lead to in situ contacts for porous semiconductors/silicon; have potential for ten-fold better luminescent emission from PSi than that obtained from anodic etching; enhance the emission of other semiconductors beyond silicon (e.g., GaN) or enable compliant substrates for heteroepitaxy; and enable creation of PSi on a variety of substrate shapes and sizes.

|

Ohmic contact degradation and gate-sinking are two major degradation mechanisms that cause semiconductor devices, such as high electron mobility transistors, or... Ohmic contact degradation and gate-sinking are two major degradation mechanisms that cause semiconductor devices, such as high electron mobility transistors, or HEMTs, to fail. In general, the rapid diffusion of contact metals into the indium phosphide substrates has restricted processing temperatures to 300C and reliable operating temperatures have been limited to 200C to 250C. This set of technologies embodies two similar methods for improving reliability and performance of contacts in indium phosphide-based semiconductors. Both alleviate the diffusion of metals into the semiconductor substrate, and the resulting impairment of device performance, by changing the composition of the metal contacts. For the first time, enhancement mode high electron mobility transistors (e-HEMTs) are practical in these material systems. Details By substituting a new metallization scheme in ohmic contacts, and an iridium-based metallization for gate contacts, processing can take place at temperatures greater than 400C, offering a processing temperature window 100C to 150C wider than was available previously. Diffusion of the metal into the substrate is reduced, thereby increasing reliability and operating lifetime. In addition, with the increased Schottky barrier height offered by the use of the new gate metallization, a true reliable indium phosphide enhancement mode HEMT, or e-HEMT, is now possible. An e-HEMT draws no power in its "off" state, a significant benefit in mobile communications applications. Applications- Wireless communications

- Satellite communications

- Defense applications

- High-frequency devices

Benefits- Higher temperature annealing

- Reduced diffusion of contact metal into substrate

- Higher reliability

- Higher temperature operation possible

- Enables true enhancement-mode high electron mobility transistors

|

Amorphous and polycrystalline III-V semiconductor including (Ga,As), (Al,As), (In,As), (Ga,N), and (Ga,P) materials were grown at low temperatures on semiconductor... Amorphous and polycrystalline III-V semiconductor including (Ga,As), (Al,As), (In,As), (Ga,N), and (Ga,P) materials were grown at low temperatures on semiconductor substrates. After growth, different substrates containing the low temperature grown material were pressed together in a pressure jig before being annealed. The annealing temperatures ranged from about 300.degree. C. to 800.degree. C. for annealing times between 30 minutes and 10 hours, depending on the bonding materials. The structures remained pressed together throughout the course of the annealing. Strong bonds were obtained for bonding layers between different substrates that were as thin as 3 nm and as thick as 600 nm. The bonds were ohmic with a relatively small resistance, optically transparent, and independent of the orientation of the underlying structures. |

In one embodiment of the present invention an oxygen iodine laser includes a gas mixing section. Ground state oxygen and a carrier gas are introduced into the... In one embodiment of the present invention an oxygen iodine laser includes a gas mixing section. Ground state oxygen and a carrier gas are introduced into the first gas mixing section, sometimes separately. The laser includes a discharge region to generate at least said excited oxygen from the flow of the first gas mixing section. A sensitizer gas having a lower ionization threshold than ground state oxygen is also introduced into the first gas mixing section, such that electrons are more easily produced in the electrical generator. The laser system includes introducing a source of iodine into the excited singlet delta oxygen flow to generate a laser-active gas. In another embodiment a conditioner is placed into the gas mixing section to help mix the flow and/or introduce one or more of the aforementioned gases. |

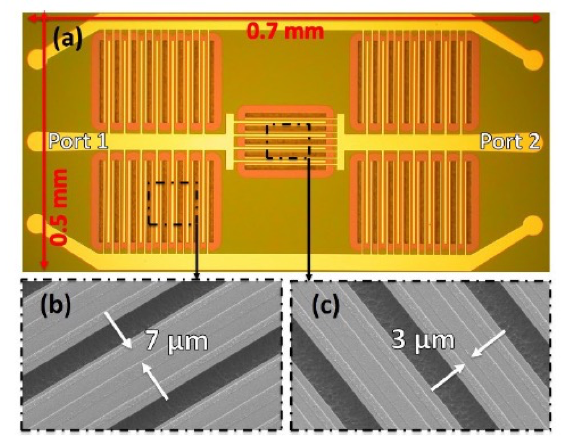

Electrohydrodynamic jet printing has been largely ignored in the high resolution graphics and electronics fabrication industries because previous methods used... Electrohydrodynamic jet printing has been largely ignored in the high resolution graphics and electronics fabrication industries because previous methods used broad and blunt nozzles that did not provide the resolutions and accuracy of other methods. Because e-jet printing also required a high voltage and led to significant positioning errors, it was restricted to use in modest resolution applications. This new approach to e-jet printing produces a higher resolution using nozzles with much smaller internal diameters than previous methods. In former methods, e-jet printing was limited to dot diameters of ~15 micrometers. This new method can produce dots as small as 250 nanometers and line widths as narrow as 700 nanometers. DetailsE-jet printing uses electric fields to create the necessary fluid flows to deliver inks to a substrate. While this approach has been explored for modest resolutions, this new approach deals specifically with high resolution printing. The e-jet uses nozzles have much smaller internal diameters than previous methods. A voltage applied between the nozzle and the metal plate allows for greater accuracy in high resolution printing. This method is now in development with multiple nozzles which will allow for greatly increased printing speed. Applications- Inkjet and printed electronics industries, as well as the security, biotechnology and photonics industries.

Benefits- Small nozzle internal diameters, less than 30 micrometers, coupled with low volt electric charge, allows for very high resolution printing.

- Can print nearly any chemical composition of ink without requiring a specific type of ink for high resolution printing.

- Distribution of electric field lines through low voltage results in minimal lateral variations and greater accuracy in high resolution printing.

- Can be used to print bulk single walled carbon nanotubes, on almost any substrate.

|

The ability to print a polarized electrical charge onto a medium, or charge patterning, is currently in the early stages of development. A similar technology... The ability to print a polarized electrical charge onto a medium, or charge patterning, is currently in the early stages of development. A similar technology commonly used in office printers, Xerography, thrives in large size regimes. There exist only a few competitive technologies capable of printing at the nanometer scale. Current technologies use processes that provide only low resolutions and relatively poor control over the printed charges. For example, current atomic force microscopy probes can provide suitable charges, but are only able for use on specialized materials. This technology has been designed to enable the printing of electrical charges on a nanoscale resolution. This technology works by modifying an E-Jet printer so that electric charges are used to manipulate a fluid medium and imprint a net positive or negative charge onto a nearly any surface. ApplicationsThis technology may be used for: - Electrostatic control of nano-electric mechanical devices

- Guided assembly of charged particles or nanostructures

- Modulation of activity in biological systems

- Invisible, printed security codes

Benefits- Enables complex patterns of alternating charge with nanoscale resolutions

- Allows highly controlled amounts of material transfer

- Printing can be performed on nearly any surface

|

Researchers from the University of Illinois have developed a process that is fully compatible with conventional foundry processes for manufacturing transient electronics.... Researchers from the University of Illinois have developed a process that is fully compatible with conventional foundry processes for manufacturing transient electronics. Utilizing conventional foundry processes allows high volume, low cost production of transient electronics which may expedite commercialization of transient technology. This technology was developed in the laboratory of Dr. John Rogers, who has received international recognition for his work on bio-integrated electronics. |

Researchers fromt the University of Illinois have developed a method of identifying and removing the metallic carbon nanotubes in an array without damaging the... Researchers fromt the University of Illinois have developed a method of identifying and removing the metallic carbon nanotubes in an array without damaging the semiconducting carbon nanotubes. The method is nearly 100% effective and scalable to large arrays. This technology enables the large-scale creation of CNT arrays with a very high I on/I off ratios. A larger ratio means less lost power while off, faster switching time, and lower operating voltage. This technology was developed in the laboratory of Dr. John Rogers, who has received international recognition for his work on bio-integrated electronics. |

Manufacturers can not achieve superconformal (bottom-up) filling of high aspect ratio features by a modified chemical vapor deposition method. The CVD precursor... Manufacturers can not achieve superconformal (bottom-up) filling of high aspect ratio features by a modified chemical vapor deposition method. The CVD precursor flux is augmented by a small flux of a growth suppressor, which slows deposition near the upper surface of the substrate while permitting growth at normal rates deep in a trench or via. DetailsAs circuit densities increase, the width of their gap structures decrease, making uniform deposition of semiconductor materials more difficult and more expensive. In order to keep-up with the demand for increasing miniaturization, transistor manufacturers have developed several novel alternatives to physical layer deposition. Among the most successful of these alternatives is Atomic Layer Deposition (ALD), a technique that essentially builds thin-film depositions one atom-layer at a time. Atomic layer deposition, however, is slow and must be repeatedly exposed to alternating reactive gasses. Electrochemical Deposition (ECD) has also been used as a solution in increasing circuit densities, but ECD is limited to certain materials and requires an additional "wet processing" step. Superconformal CVD avoids these obstacles through super heating elemental hydrogen or nitrogen, changing the gas into its atomic, or plasmatic, state. During the chemical deposition process, a plasma beam that is directed at the substrate suppresses the chemical reaction along the surface of the etched wafer, preventing undesirable material accumulation around the cusp of the wafer's trenches. ApplicationsFor use in the development of micro- and nano-scale semiconductor devices, Superconformal CVD gives producers of microchips, MEMS, and various other microelectronic devices greater control over their manufacturing process. All current methods of CVD: Superconformal CVD has been demonstrated to be successful for the deposition of several different types of materials. The technique should be widely applicable for the superconformal deposition of essentially any material, although additional development work may be required to identify the best combination of suppressor gas and growth gas. BenefitsThe semiconductor device industry strives to develop manufacturing techniques to meet increasingly stringent design rules. By offering a gas-phase method for achieving superconformal, bottom-up filling of features with high aspect-ratios, this technology solves a long-standing manufacturing obstacle. - Eliminates Pinch-off: Pinch-off occurs when unwanted film deposition near the opening of a trench or via accumulates to the point that the gap closes. Pinch-off creates voids within a trench or via, resulting in reduced device performance. These problems have proven difficult to overcome; alternative manufacturing methods - atomic layer deposition (ALD) and electrochemical deposition (ECD) - require several extra steps.

- Fast and inexpensive: Our Superconformal Chemical Vapor Deposition method is fast and inexpensive and does not require extra chemical washing or polishing steps. The process is compatible with existing microelectronic manufacturing methods.

- Clean deposition: Atomic hydrogen often serves as an effective suppressor gas, and a significant advantage of its use is that impurities are not introduced that could compromise device performance. The metastable nature of the atomic hydrogen ensures that it rapidly recombines on and desorbs from the surface as molecular hydrogen gas.

- High Aspect Ratio Processes: With our improved method, pinch-off is reduced or eliminated, often achieving complete filling even for aspect ratios as high as 50:1.

|

This technology is a family of metal complexes that can be used for depositing metal compounds. This technology is a family of metal complexes that can be used for depositing metal compounds. |

Dr. Bahl from the University of Illinois has discovered a new method to create non-reciprocal property without using external magnetic field. The method employs... Dr. Bahl from the University of Illinois has discovered a new method to create non-reciprocal property without using external magnetic field. The method employs Brillouin Stimulated Induced Transparency (BSIT), by adding a laser and a specifically designed microns-sized resonator. Applying BSIT can significantly reduce the size and cost, and also bring about the possibility for magnet-free on-chip application. |

Dr. Bailey from the University of IL has invented a new fluidic device for droplet manipulation for use in droplet-based analysis, such as PCR in DNA sequencing.... Dr. Bailey from the University of IL has invented a new fluidic device for droplet manipulation for use in droplet-based analysis, such as PCR in DNA sequencing. Sample preparation has been longing an high through-put, automated solution due to its intensive labor cost. This chip-scale fluidic device enables multiple droplet manipulations, such as splitting, addition, extraction in one single geometry. With further development it even has possibility to change droplet concentration. |

The invention improves the process of ion implantation and annealing, which is used to introduce dopants into a semiconductor to make pn junctions. The... The invention improves the process of ion implantation and annealing, which is used to introduce dopants into a semiconductor to make pn junctions. The improvements control the motion of bulk semiconductor defects such as interstitial atoms through control of surface chemistry. This leads to a reduction of the depth and electrical resistance of the pn junction. DetailsThe invention concerns process improvements to ion implantation and annealing technology, which is used to introduce dopants into a semiconductor in order to make pn junctions. The improvements control the motion of bulk semiconductor defects such as interstitial atoms through control of surface chemistry. The surface chemistry changes the intrinsic ability of the surface to absorb defects that diffuse to it. The preferential loss of Si interstitials keeps electrically active dopant fixed in the lattice by inhibiting the "kick out" reaction that makes such dopant atoms mobile and inactive. The interstitial loss rate is controlled by the introduction of an additional step in the annealing process. The surface chemistry also changes the interaction of electrically charged defects with charges at the surface by greatly reducing the charge buildup at the surface and therefore reducing the surface repulsion effect, which increases the activated dopant concentration. ApplicationsThis technology can be applied to almost any product that uses higher end (< 90 nm) integrated circuits. Not relevant to technologies that use lower resolution since current pn junction technology is acceptable. Examples of such applications include: - Computers

- Communications

- Electronics

Benefits- Pn junction with reduced depth and increased dopant activation: Leads to transistor devices with higher performance

- Compatible with current manufacturing technologies: Avoids the large costs associated with paradigm-changing technologies

- Adjusted loss rate of interstitials to the surface: Offers highly controllable mechanism for defect engineering.

|

The invention provides a quantum well active region for an optoelectronic device. The quantum well active region includes barrier layers of high bandgap material.... The invention provides a quantum well active region for an optoelectronic device. The quantum well active region includes barrier layers of high bandgap material. A quantum well of low bandgap material is between the barrier layers. Three-dimensional high bandgap barriers are in the quantum well. A preferred semiconductor laser of the invention includes a quantum well active region of the invention. Cladding layers are around the quantum well active region, as well as a waveguide structure. |

A semiconductor laser that includes an active region, claddings and electrical contacts to stimulate emissions from the active region, where a coupled waveguide... A semiconductor laser that includes an active region, claddings and electrical contacts to stimulate emissions from the active region, where a coupled waveguide guides emission. The waveguide includes a broad area straight coupling region that fans out into an array of narrower Individual curved coupled waveguides at an output facet of the laser. The individual curved coupled waveguides are curved according to Lorentzian functions that define the waveguide curvature as a function of position along the device. The integral length of each individual curved coupled waveguide differs from adjacent individual curved coupled waveguides by an odd number of half-wavelengths. The coupled waveguide array shapes the optical field output of the semiconductor laser such that a large fraction of the power is emitted into a small angular distribution using interference phenomena. A laser of the invention produces high power output with a very high quality, narrow beam shape. |

A method for producing light emission, including the following steps: providing a transistor structure that includes a semiconductor base region disposed between a... A method for producing light emission, including the following steps: providing a transistor structure that includes a semiconductor base region disposed between a semiconductor emitter region and a semiconductor collector region; providing a cascade region between the base region and the collector region, the cascade region having a plurality of sequences of quantum size regions, the quantum size regions of the sequences varying, in the direction toward the collector region, from a relatively higher energy state to a relatively lower energy state; providing emitter, base and collector electrodes respectively coupled with the emitter, base, and collector regions; and applying electrical signals with respect to the emitter, base, and collector electrodes to cause and control light emission from the cascade region. |

Researchers from the University of Illinois have developed a method for vertical-cavity surface-emitting laser (VCSEL) to provide high-power output with good beam... Researchers from the University of Illinois have developed a method for vertical-cavity surface-emitting laser (VCSEL) to provide high-power output with good beam quality. The method use Zn-diffusion to create disordering and filter out high order mode of the laser. As a result, VCSEL with larger aperture, which permits higher power, will still output single mode light with tight focus. This technology provides laser for energy-assisted magnetic recording, which could be used in next generation hard disk drive. |

This invention allows for the production of a family of photodetectors that are sensitive in the ultraviolet, visible, and near-infrared regions of the spectrum.... This invention allows for the production of a family of photodetectors that are sensitive in the ultraviolet, visible, and near-infrared regions of the spectrum. Despite previous knowledge of photo responses to low pressure gas discharges, this technology is the first to achieve these responses without using plasma as the photosensitive element. The plasma instead amplifies the number of photoelectrons produced by the cathode's avalanche effect. Furthermore, the electronic properties of the photocathode material determine the spectral response of the photodetector. These photocathodes can then be composed of different materials to optimize the photodetector for more specific responsiveness. DetailsAs the spatial dimensions of microplasma devices have continued to decrease they have become attractive for an increasingly wide range of applications. The microdischarge devices this technology enables are sensitive detectors of visible, near-IR, and UV radiation and significantly extend the use of silicon devices. The wavelength range over which microdischarge detectors are photosensitive can be extended by simply changing the photocathode material Therefore, detectors have a significant advantage over their semiconductor counterparts because of the wavelength agility available with a single, rugged device structure. Furthermore, the crystalline quality of the semiconductor photocathode in the microplasma device is unlikely to be critical. Consequently, one has the option of micromachining the detector from silicon and overcoating the cathode with a film of the appropriate semiconductor (or other material). Since this detector is fabricated in silicon, large arrays of devices can be produced economically. To date, arrays as large as 250,000 (500 x 500) have been tested successfully. These photodetectors combined with other advances in microdischarge technology lead to a bright future for nearly any application involving light. Information about other devices and applications using UIUC Microdischarge technology is available on request. Benefits- Amenable to mass production: This invention can be readily integrated with other electronic or optoelectronic devices.

- Inexpensive: Because this device does not depend on the existence of a p-n junction the crystalline quality of the semiconductor is not an issue.

- More sensitive: This invention provides a photodetector in the visible and UV that is considerably more sensitive than commercial Si photodiodes.

|

The invention provides in one of the embodiments for either a continuous wave (cw) or pulsed alkali laser having an optical cavity resonant at a wavelength defined... The invention provides in one of the embodiments for either a continuous wave (cw) or pulsed alkali laser having an optical cavity resonant at a wavelength defined by an atomic transition, a van der Waals complex within the optical cavity, the van der Waals complex is formed from an alkali vapor joined with a polarizable gas, and a pump laser for optically pumping the van der Waals complex outside of the Lorentzian spectral wings wherein the van der Waals complex is excited to form an exciplex that dissociates forming an excited alkali vapor, generating laser emission output at the wavelength of the lasing transition. |

Plasma-based electronic devices assumed a significant role in communications and display systems in the first half of the 20th century. One example is the plasma... Plasma-based electronic devices assumed a significant role in communications and display systems in the first half of the 20th century. One example is the plasma voltage regulator (such as the OA, OB, OC, and OD series of rare gas plasma voltage regulators and electronic switches, and the 866A mercury plasma high voltage tube) that was widely incorporated into RF transmitters. This invention demonstrates that portions of a semiconductor transistor can be replaced by plasma, yielding a new family of three terminals, hybrid plasma electronic devices having properties previously unavailable. DetailsThis invention provides hybrid semiconductor-plasma transistors in which the plasma replaces at least one semiconductor portion of a conventional transistor. Preferred embodiments of the invention provide a plasma bipolar junction transistor (PBJT) in which a plasma serves as the collector for an npn BJT. As the plasma conducts current, light is emitted that can be modulated by imposing a time-varying voltage across (or current through) the emitter-base junction of the PBJT. In this and other devices of the invention, the plasma may either be micro-cavity plasma, offering reduced volume and enhanced electron densities relative to macro-scopic plasma, or a larger volume (conventional) low temperature plasma. Other preferred embodiments of the invention provide plasma MOSFET devices in which plasma controls the conductance of the channel in a MOSFET. Applications- Ultra High Resolution

- Plasma Displays

- Next Generation

- Flexible Displays

- Biomedical and Environmental Sensors

- Micro-analytical Instruments having low power consumption

- 3D chips Other applications where traditional transistors are used

BenefitsThese transistors have reduced volumes and are thinner thus the devices formed with these transistors will be smaller and can be used in newer potential applications. The plasma transistors have enhanced electron densities and the plasma modulation can be controlled with very low voltages for the first time and thus the devices will be faster and very energy efficient. |

Researchers at the University of Illinois have developed a new laser pumping method which provides efficient and continuous high power (>10W) lasers in the... Researchers at the University of Illinois have developed a new laser pumping method which provides efficient and continuous high power (>10W) lasers in the visible, ultraviolet, and near-infrared regions in both gas and solid state systems. This method allows cooling of the laser medium while achieving over 100% quantum efficiency. Combined with frequency doubling this laser should yield more than 10 watts of violet (426 or 427 nm), a region of the spectrum in which no powerful sources exist. |

Electrochemical fabrication platforms for making structures, arrays of structures and functional devices having selected nanosized and/or microsized physical... Electrochemical fabrication platforms for making structures, arrays of structures and functional devices having selected nanosized and/or microsized physical dimensions, shapes and spatial orientations. Methods, systems and system components use an electrochemical stamping tool such as solid state polymeric electrolytes for generating patterns of relief and/or recessed features exhibiting excellent reproducibility, pattern fidelity and resolution on surfaces of solid state ionic conductors and in metal. Electrochemical stamping tools are capable high throughput patterning of large substrate areas, are compatible with commercially attractive manufacturing pathways to access a range of functional systems and devices including nano- and micro-electromechanical systems, sensors, energy storage devices, metal masks for printing, interconnects, and integrated electronic circuits. |

This invention is the world's first light emitting transistor. The HBLET extends the capabilities of light-emitting diodes and could make this transistor the... This invention is the world's first light emitting transistor. The HBLET extends the capabilities of light-emitting diodes and could make this transistor the fundamental element in electronics and optoelectronics. DetailsIn a bipolar device there are two kinds of injected carriers, negatively charged electrons and positively charged holes. Some of these carriers, for example, a transistor, recombine rapidly, supported by a base current essential for normal transistor function. In the past, this base current has been regarded as a waste current that generates unwanted heat. However, this technology shows the base current creates light that can be modulated at transistor speed. This recombination process is the same (but enhanced by carrier transport) as the one used in LEDs to produce visible, rather than infared, light. The transistor laser produces infared radiation in phase with its base current, so it can be modulated at a switching speed impossible to attain with an LED. The switching speed obtained is fast enought to operate in fiber optic networks, as well as other applications. These transistors are made with indium gallium phosphide and gallium arsenide, unlike traditional transistors which have been built from silicon and germanium. The recombination process in indium gallium phosphide and gallium arsenide materials create infared photons, the "light" in the light emitting transistor. This contributes to the device's ability to operate as both a laser and a transistor. The existence of a third port (the photon output) can interconnect optical and electric signals for display or communication purposes. Additionally, electrical and optical qualities are increased by the incorporation of quantum wells into the active region of the transistors. The transistor laser has a unique capability in signal processing and electronic-photonic integrated circuits. Applications- Electronics

- Optoelectronics

- Displays

Benefits- Speed: These transistors produce infared light in phase with their base current, allowing it to attain a switching speed superior to light emitting diodes (LEDs).

- Controlled light emission: Light intensity can be controlled by varying the base current.

- Simultaneous control of optical and electrical outputs: The addition of a third port allows greater control.

- Utilizes base current: Once considered wasteful, the base current is used to create light.

|

This invention is the world's first light emitting transistor. The HBLET extends the capabilities of light-emitting diodes and could make this transistor the... This invention is the world's first light emitting transistor. The HBLET extends the capabilities of light-emitting diodes and could make this transistor the fundamental element in electronics and optoelectronics. Details In a bipolar device there are two kinds of injected carriers, negatively charged electrons and positively charged holes. Some of these carriers, for example, a transistor, recombine rapidly, supported by a base current essential for normal transistor function. In the past, this base current has been regarded as a waste current that generates unwanted heat. However, this technology shows the base current creates light that can be modulated at transistor speed. This recombination process is the same (but enhanced by carrier transport) as the one used in LEDs to produce visible, rather than infared, light. The transistor laser produces infared radiation in phase with its base current, so it can be modulated at a switching speed impossible to attain with an LED. The switching speed obtained is fast enought to operate in fiber optic networks, as well as other applications. These transistors are made with indium gallium phosphide and gallium arsenide, unlike traditional transistors which have been built from silicon and germanium. The recombination process in indium gallium phosphide and gallium arsenide materials create infared photons, the "light" in the light emitting transistor. This contributes to the device's ability to operate as both a laser and a transistor. The existence of a third port (the photon output) can interconnect optical and electric signals for display or communication purposes. Additionally, electrical and optical qualities are increased by the incorporation of quantum wells into the active region of the transistors. The transistor laser has a unique capability in signal processing and electronic-photonic integrated circuits. Applications- Electronics

- Optoelectronics

- Displays

Benefits- Speed: These transistors produce infared light in phase with their base current, allowing it to attain a switching speed superior to light emitting diodes (LEDs). Controlled light emission Light intensity can be controlled by varying the base current. Simultaneous control of optical and electrical outputs The addition of a third port allows greater control. Utilizes base current Once considered wasteful, the base current is used to create light.

|

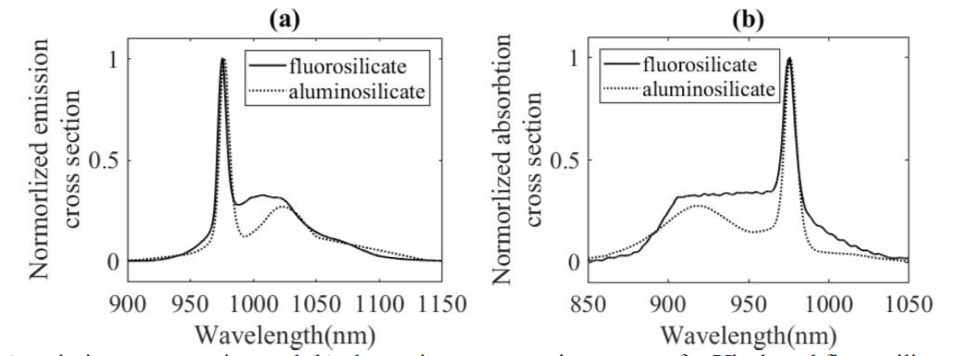

Researchers at the University of Illinois have improved the performance of a Quantum Well Transistor and Laser. Their invention helps improve the performance of... Researchers at the University of Illinois have improved the performance of a Quantum Well Transistor and Laser. Their invention helps improve the performance of optical communications systems and can also be used to determine the noise figure of semiconductor optical amplifiers. Overview of the Transistor Laser (from the website of Professor Feng)Described in the Novermeber 15 issue of the journal Applied Physics Letters in 2004, Milton Feng, Nick Holonyak, postdoctoral research associate Gabriel Walter, and graduate research assistant Richard Chan demonstrated operation of the first heterojunction bipolar transistor laser by incorporating quantum well in the active region of light emitting transistor. Just as light emitting transistor, transistor laser was made of indium gallium phosphide, indium gallium arsenide, and gallium arsenide, but emitted coherent beam by stimulated emission, which differed from their previous device that only emitted incoherent photons. Despite their success, the device was not useful for practical purposes since it only operated at low temperatures about minus 75 in Celsius degrees. Within a year, though, the researchers finally fabricated a transistor laser operating at room temperature by using metal organic chemical vapor deposition (MOCVD), as reported in the September 26 issue of the same journal. At this time, the transistor laser had 14-layer structure including aluminium gallium arsenide optical confining layers and indium gallium arsenide quantum wells. The emitting cavity was 2,200nm wide, 0.85mm long, had continuous modes at 1,000nm. Plus, it had threshold current of 40mA and direct modulation of the laser at 3 GHz. |

MEMS stages comprising a plurality of comb drive actuators provide micro and up to nano-positioning capability. Flexure hinges and folded springs that operably... MEMS stages comprising a plurality of comb drive actuators provide micro and up to nano-positioning capability. Flexure hinges and folded springs that operably connect the actuator to a movable end stage provide independent motion from each of the actuators that minimizes unwanted off-axis displacement, particularly for three-dimensional movement of a cantilever. Also provided are methods for using and making MEMS stages. In an aspect, a process provides a unitary MEMS stage made from a silicon-on-insulator wafer that avoids any post-fabrication assembly steps. Further provided are various devices that incorporate any of the stages disclosed herein, such as devices requiring accurate positioning systems in applications including scanning probe microscopy, E-jet printing, near-field optic sensing, cell probing and material characterization. |

This invention is the world's first light emitting transistor. The HBLET extends the capabilities of light-emitting diodes and could make this transistor the... This invention is the world's first light emitting transistor. The HBLET extends the capabilities of light-emitting diodes and could make this transistor the fundamental element in electronics and optoelectronics. DetailsIn a bipolar device there are two kinds of injected carriers, negatively charged electrons and positively charged holes. Some of these carriers, for example, a transistor, recombine rapidly, supported by a base current essential for normal transistor function. In the past, this base current has been regarded as a waste current that generates unwanted heat. However, this technology shows the base current creates light that can be modulated at transistor speed. This recombination process is the same (but enhanced by carrier transport) as the one used in LEDs to produce visible, rather than infared, light. The transistor laser produces infared radiation in phase with its base current, so it can be modulated at a switching speed impossible to attain with an LED. The switching speed obtained is fast enought to operate in fiber optic networks, as well as other applications. These transistors are made with indium gallium phosphide and gallium arsenide, unlike traditional transistors which have been built from silicon and germanium. The recombination process in indium gallium phosphide and gallium arsenide materials create infared photons, the "light" in the light emitting transistor. This contributes to the device's ability to operate as both a laser and a transistor. The existence of a third port (the photon output) can interconnect optical and electric signals for display or communication purposes. Additionally, electrical and optical qualities are increased by the incorporation of quantum wells into the active region of the transistors. The transistor laser has a unique capability in signal processing and electronic-photonic integrated circuits. Applications- Electronics

- Optoelectronics

- Displays

Benefits- Speed: These transistors produce infared light in phase with their base current, allowing it to attain a switching speed superior to light emitting diodes (LEDs).

- Controlled light emission: Light intensity can be controlled by varying the base current.

- Simultaneous control of optical and electrical outputs: The addition of a third port allows greater control.

- Utilizes base current: Once considered wasteful, the base current is used to create light.

|

A two terminal semiconductor device for producing light emission in response to electrical signals, includes: a terminal-less semiconductor base region disposed... A two terminal semiconductor device for producing light emission in response to electrical signals, includes: a terminal-less semiconductor base region disposed between a semiconductor emitter region and a semiconductor collector region having a tunnel junction adjacent the base region; the base region having a region therein exhibiting quantum size effects; an emitter terminal and a collector terminal respectively coupled with the emitter region and the collector region; whereby application of the electrical signals with respect to the emitter and collector terminals, causes light emission from the base region. Application of the electrical signals is operative to reverse bias the tunnel junction. Holes generated at the tunnel junction recombine in the base region with electrons flowing into the base region, resulting in the light emission. The region exhibiting quantum size effects is operative to aid recombination. |

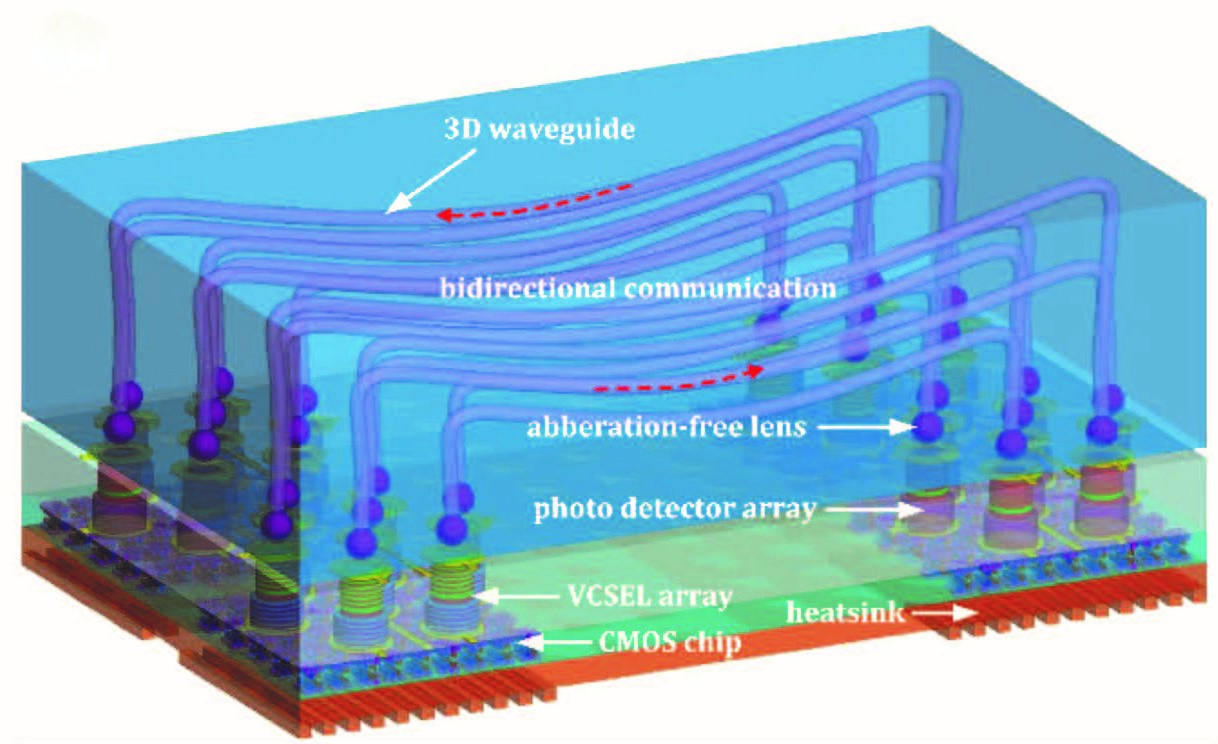

Semiconductor light emitting diodes (LEDs) and lasers using direct gap III-V materials and electron-hole injection and recombination, have over the years led to... Semiconductor light emitting diodes (LEDs) and lasers using direct gap III-V materials and electron-hole injection and recombination, have over the years led to numerous applications in display and light-wave communications. While semiconductor lasers typically dominate long-distance communications links, fast spontaneous light-wave can be an attractive solution for short range optical data communications and optical interconnections as their threshold-less operation, high fabrication yield and reduced driver and feedback control complexity significantly reduce the overall cost, form factor and power consumption of transmitters. However, the fastest spontaneous light source shown to date (a light emitting diode) employs p-doping as high as 7X1019 cm-3 to achieve a bandwidth of 1.7 GHz, at the cost of reduced internal quantum efficiency to 10% or less. In practice, higher efficiency spontaneous devices such as LEDs or RCLEDs operate with bandwidths that are less than 1 GHz, restricting actual commercial application of spontaneous light transmitters (LEDs and RCLEDs) to less than 1 Gbits/s. With this technology an improved 4.3 GHz optical microwave performance of a three-port light emitting transistor is achieved. DetailsThe hetero-junction bipolar light emitting transistor (HBLET), which uses a high-speed hetero-junction bipolar transistor (HBT) structure, could potentially function as a light source with speeds exceeding tens of GHz. The room temperature, continuous wave operation of a transistor laser further demonstrates that a practical radiative recombination center (i.e. undoped quantum well) can be incorporated in the heavily doped base region of a HBLET. In practice, despite the high intrinsic speed of the HBT, the microwave performance of an HBLET is severely limited by parasitic capacitances, partly owing to the need to include light extraction features (such as oxide apertures) not present in traditional high speed HBT devices. With this technology an improved 4.3 GHz optical microwave performance of a three-port light emitting transistor is achieved which significantly reduces the overall parasitic capacitances. Also, the three-terminal nature of the light emitting transistor offers two input-output configurations for electrical-to-optical output conversion, e.g., via the common-collector BC- and EC-input ports, each with its own unique advantages. ApplicationsTogether with the advantages of higher yield, reduced complexity and three-terminal high-speed modulation capabilities as both a transistor (amplifier and switch) and electrical-to-optical convertor, the HBLET could be an attractive solution for short range optical data communications, and has significant implications for the development of high-speed semiconductor lasers and integrated optoelectronics. BenefitsThis hetero-junction bipolar light emitting transistor (HBLET) technology indicates that spontaneous recombination can be fast and higher modulation speeds are possible by further reducing the undesirable parasitic. In addition, due to the absence of the relaxation oscillations typically observed in laser devices and the lesser attenuation slope, an HBLET could potentially be deployed at data rates much higher than 4.3 Gb/s. Together with the advantages of higher yield, reduced complexity and three-terminal high-speed modulation capabilities as both a transistor (amplifier and switch) and electrical-to-optical convertor, the HBLET could be an attractive solution for short range optical data communications, and has significant implications for the development of high-speed semiconductor lasers and integrated optoelectronics. |

This invention provides processing steps, methods and materials strategies for making patterns of structures for electronic, optical and optoelectronic devices.... This invention provides processing steps, methods and materials strategies for making patterns of structures for electronic, optical and optoelectronic devices. Processing methods of the present invention are capable of making micro- and nano-scale electronic structures, such as T-gates, gamma gates, and shifted T-gates, having a selected non-uniform cross-sectional geometry. The technology provides lithographic processing strategies for sub-pixel patterning in a single layer of photoresist useful for making and integrating device components comprising dielectric, conducting, metal or semiconductor structures having non-uniform cross-sectional geometries. Processing methods of the present invention are complementary to conventional microfabrication and nanofabrication platforms, and can be effectively integrated into existing photolithographic, etching and thin film deposition patterning strategies, systems and infrastructure. |

This invention provides processing steps, methods and materials strategies for making patterns of structures for integrated electronic devices and systems.... This invention provides processing steps, methods and materials strategies for making patterns of structures for integrated electronic devices and systems. Processing methods of the present invention are capable of making micro- and nano-scale structures, such as Dual Damascene profiles, recessed features and interconnect structures, having non-uniform cross-sectional geometries useful for establishing electrical contact between device components of an electronic device. The invention provides device fabrication methods and processing strategies using sub pixel-voting lithographic patterning of a single layer of photoresist useful for fabricating and integrating multilevel interconnect structures for high performance electronic or opto-electronic devices, particularly useful for Very Large Scale Integrated (VLSI) and Ultra large Scale Integrated (ULSI) devices. Processing methods of the present invention are complementary to conventional microfabrication and nanofabrication methods for making integrated electronics, and can be effectively integrated into existing photolithographic, etching, and thin film deposition patterning systems, processes and infrastructure. |

This invention provides photoablation--based processing techniques and materials strategies for making, assembling and integrating patterns of materials for the... This invention provides photoablation--based processing techniques and materials strategies for making, assembling and integrating patterns of materials for the fabrication of electronic, optical and opto-electronic devices. Processing techniques of the present invention enable high resolution and/or large area patterning and integration of porous and/or nano- or micro-structured materials comprising active or passive components of a range of electronic devices, including integrated circuits (IC), microelectronic and macroelectronic systems, microfluidic devices, biomedical devices, sensing devices and device arrays, and nano- and microelectromechanical systems. |

Described herein are processing techniques for fabrication of stretchable and/or flexible electronic devices using laser ablation patterning methods. The laser... Described herein are processing techniques for fabrication of stretchable and/or flexible electronic devices using laser ablation patterning methods. The laser ablation patterning methods allow for efficient manufacture of large area (e.g., up to 1 mm.sup.2 or greater or 1 m.sup.2 or greater) stretchable and/or flexible electronic devices, for example manufacturing methods permitting a reduced number of steps. The techniques further provide for improved heterogeneous integration of components within an electronic device, for example components having improved alignment and/or relative positioning within an electronic device. Also described are flexible and/or stretchable electronic devices, such as interconnects, sensors and actuators. |

This invention is a class of micromirrors with high reflectivity dielectric layer coated on top of micromirror that can be tuned to allow transparency or... This invention is a class of micromirrors with high reflectivity dielectric layer coated on top of micromirror that can be tuned to allow transparency or reflectivity of UV or Visible light to meet the needs of the application. Also disclosed is a top-down fabrication process for the assembly of coated micromirrors using polymer structural material. Includes additional features & methods for: phase shift mask, sharp turn off, flexible micromirror arrays, and thermal compensation. |

Dr. Seok Kim from the University of Illinois has developed a method to fabricate a silicon-based MEMS mirror and its elastomeric universal joint. This method,... Dr. Seok Kim from the University of Illinois has developed a method to fabricate a silicon-based MEMS mirror and its elastomeric universal joint. This method, termed micro-masonry, can be extended to integrate elastomer and silicon components, thus enabling strong mechanical and electrical connections between two heterogeneous materials without causing the damage of elastomer. As a result, the fabricated device could exhibit 3D motion in a compact gimballess design. |

Temperature limits the sensitivity and resolution of every surface electrical potential measurement made by an AFM today. With existing AFM probes, temperature and... Temperature limits the sensitivity and resolution of every surface electrical potential measurement made by an AFM today. With existing AFM probes, temperature and current cannot be modulated, thus it is difficult to control temperature or to measure electrical potential at the tip. This device uses an integrated resistive heating element and temperature controls to combine temperature applications with voltage measurements to remove the uncertainty of temperature in surface electrical potential measurements. Using an integrated resistive heating element, the device has the ability to reach 1000 C and can control the temperature of the AFM probe tip to measure the tip's electrical resistance. This device makes nanoscale surface electrical potential measurements that may be a function of temperature. As this technique modulates the temperature precisely, it removes the temperature uncertainty of surface electrical potential measurements. Using multiple probes on a single chip, the device also addresses the slow-throughput of Dip Pen Nanolithography Applications:Semiconductor and surface science as well as repair applications in photo-mask and flat panel displays. Benefits:The ability to calibrate and control AFM tip temperature within 1C at temperatures greater than 1000 C. Multiple AFM probes that can be manufactured in bulk and can be addressed individually. |

Thermal sensitivity in piezoresistive sensors used in silicon microcantilevers makes them susceptible to unwanted signals such as temperature drift. In addition,... Thermal sensitivity in piezoresistive sensors used in silicon microcantilevers makes them susceptible to unwanted signals such as temperature drift. In addition, when used in chemical sensing, current microcantilevers have difficulty testing femtogram (10-15) scale samples due to the effect of temperature variations on the mechanical signal. This invention is a microcantilever hotplate with both a resistive heater and temperature-compensated piezoresistive strain gauges that correct for the effect of temperature variations on the mechanical strain signal. This enables the ability to test samples in femtogram quantities allowing the preservation of highly valuable materials such as DNA samples or new drug compounds. In contrast, samples tested on the milligram scale prove to be costly since the samples are often discarded after testing. Microcantilevers with integrated piezoresistive strain sensors are mainly used to replace optical (laser) deflection sensing thus reducing design complexity and cost. They may also be employed in various sensing applications such as gas flow sensing, acceleration sensing, microjet measurements and bio/chemical sensing. As bio/chemical sensors, piezoresistive microcantilevers are often prepared with a selective coating that is sensitive to a specific analyte. Analyte adsorption induces static deflection of the microcantilever by creating a surface stress, thus enabling embedded piezoresistors to measure analyte adsorption on the cantilever. Microcantilevers with both resistive heaters and piezoresistors can also offer simultaneous heating and sensing. Two different cantilever designs with the same surface area have been designed with integrated heaters along the cantilever edges and a pair of piezoresistors for temperature-compensated strain gauges. The fabricated devices show successful integration of resistive heaters and piezoresistors. These microcantilever hotplates could enable simultaneous calorimetric and thermogravimeteric measurements by operating the heater and the piezoresistor pair together. Applications Thermomechanical data storage, biomorph actuation; nanoscale thermal analysis and manufacturing; material diagnostic characterization; calorimetry; and biochemical sensing. Benefits- Improves response time and enhances temperature uniformity

- Combines resistive heaters and piezoresistors on a microcantilever, which can be used as multi-functional scanning probes

- Enables materials testing at the femtogram scale

- A pair of piezoresistors in close proximity and aligned at 45, means excellent temperature compensation: 10 percent shift in deflection sensitivity for heating up to 200 C