A power converter circuit to convert multiple direct current (dc) inputs to one or more dc outputs. This dc-dc power converter allows its load to be powered by multiple,... A power converter circuit to convert multiple direct current (dc) inputs to one or more dc outputs. This dc-dc power converter allows its load to be powered by multiple, different sources of various voltage and current levels (such as solar panels, batteries, fuel cells, etc.). This converter has both buck and boost capability. This circuit can simultaneously draw power from several dc electrical energy sources of different kinds (such as solar panels, batteries, fuel cells, etc.). The circuit topology is capable of an arbitrary number of input sources of different voltage/current/power levels. There is a single output voltage that can directly supply a load, or can supply another power converter. The default circuit uses an inductor, but it may be substituted with a transformer to provide electrical isolation or multiple output as well. The power flow from each source can be controlled separately in order to optimize the power flow characteristics for cost, environmental protection, or any other performance objective. Low power applications regulate source switching with a control circuit. High power applications regulate and optimize flow characteristics with a digital signal processor (DSP). This circuit contains a minimum number of components which reduce overall complexity and cost when compared to other implementations. In addition, due to efficiency in design, this circuit can be scaled to work across a multitude of power ranges. Applications:This technology can be used in any application which uses multiple dc energy sources and in situations where backup or simultaneous alternative energy sources are used. Such sources include solar cells, fuel cells, batteries, and thermoelectric sources. Benefits:- Simple: Designed with minimal parts, allowing for reduced complexity in design and higher reliability.

- Low Cost: Requires fewer inductors and transistors when compared to equivalent dc-dc converters, therefore manufacturing costs are reduced.

- Efficient: Less loss and higher conversion efficiency due to the minimal design parts.

- Adaptable: Easily integrated into existing systems and combined with other converters (i.e. ac-dc).

To license the entire Solar Panels portfolio, click here . |

This technology is a process for preparing biodegradable resins comprised of corn zein and fatty acids and forming the resins into sheets, thin films, and similar... This technology is a process for preparing biodegradable resins comprised of corn zein and fatty acids and forming the resins into sheets, thin films, and similar products useful in a broad range of food packaging and agricultural applications. Corn zein-based Biodegradable Resins present an environmentally friendly alternative to plastic. Zein resins are new products derived from corn zein. Zein, a family of proteins found in corn, is solvent extracted, mixed with long chain fatty acids, chilled, washed and kneaded to form a moldable biodegradable plastic which can be extruded immediately to form products or pellitized for later use. Pellets can be stored or shipped to plastic mills to be formed into highly useable, edible, biodegradable, environmentally friendly products. Applications- Consumer Replacement for plastic packaging materials such as trash and grocery bags; shrink films used to protect palletized products; food wraps used to prevent spoilage; or disposable food service ware such as plates, bowls, and cups.

- Agricultural Weed Control: Rolled films produced from zein resin can be applied to planting beds or placed between row crops to prevent weeds. Since the product is fully biodegradable, there's no need to remove the preventative layer at the end of the growing season; saving time and money.

- Cover for Round Hay Bales: Zein-based resin films can be used to protect hay bales from spoiling. Zein-based resins are completely edible; therefore, films do not need to be removed prior to their use.

- Horticulture Containers manufactured from zein-based resins go directly from the green-house to a consumer's garden or planting bed, saving disposal of traditional plastic pots.

Benefits - Multiple End-Use Products: Products manufactured from zein-based resins can be extruded, blown, or injection molded into a wide variety of forms. Examples include trays, bowls, clamshells, films which can be used for wraps and/or laminated, and edible hay bale wrappers.

- Desirable Production Characteristics: Zein bioplastics are flexible, tough, heat sealable, able to accept color pigmentation, and producible in varying degrees of oxygen and carbon dioxide permeability.

- Fully Biodegradable: Unlike commodity plastics that do not degrade, products manufactured from zein-based resins are completely biodegradable by native soil microflora; leaving no residual materials to dispose of or fear of ingestion by wildlife or production animals.

- Abundance of Raw Material: Zein resins are derived from corn. Zein-based resins are categorized by the FDA as "Generally Recognized as Safe" (GRAS): Products manufactured from zein-based resins can be used to package and/or protect food stuffs.

|

Researchers from the Beckman institute at the University of Illinois are developing a system for cooling structural materials inspired on nature's transpiration.... Researchers from the Beckman institute at the University of Illinois are developing a system for cooling structural materials inspired on nature's transpiration. Using porous materials and leveraging capillary forces, Scott White's lab created a transpiration system to cool down a surface. The system is autonomous, self powered, and inexpensive. In addition, the principle of transpiration make this cooling solution self regulated requiring minimum user input after the system is installed. The new system will enable the use of polymer materials for applications where high temperatures would degrade non-cooled polymers.

|

This technique for liquid composite molding uses a solid catalyst recrystallized onto preplaced fiber reinforcements to produce high-strength polymer matrix... This technique for liquid composite molding uses a solid catalyst recrystallized onto preplaced fiber reinforcements to produce high-strength polymer matrix composites. The polymerization is initiated by the preform itself, eliminating the need to mix multiple resins and catalysts before filling the mold. Having polymerization triggered by the preform simplifies the process, saves time, and eliminates mixing equipment. Liquid composite molding processes have been popular since the 1940s. In the last 10 to 15 years, significant improvements have been made in developing low-viscosity thermosetting resin systems necessary to obtain high fiber volume parts. Also, automatic methods like weaving, braiding, and knitting have greatly reduced the cost of producing fiber preforms. All liquid composite molding processes require that the resin injected into the mold is a reactive liquid. Some resins such as epoxy and urethane are highly reactive and must be kept separate until just before they are injected into the mold. Other resins are activated by a catalyst in the holding tank. These multipart resin systems require complex mixing, metering, and use of injection equipment with accurate ratio control. The multipart resin systems also may require heating tanks, hoses, pipes, and pumps; motionless mixing; efficient circulation to help prevent cure or degradation of the resin in a holding tank; and easy and safe cleaning/purging. This new liquid composite molding technique uses a one-part monomer and a solid catalyst crystallized onto the fiber reinforcement. The polymerization is initiated by the preform itself, eliminating the need to mix or add multiple resins and catalysts before filling the mold. Since it uses a single resin, the process also eliminates the need for the mixing equipment and reduces the heating and cleaning requirements of the injection equipment. The best material system for use with this technology is one that uses polydicyclopentadiene (pDCPD). This polymer forms very rapidly at room temperature by a ring-opening metathesis polymerization (ROMP) of its low-viscosity monomer. The first step in this process requires recrystallizing the catalyst onto the fiber preform. The reactive fiber preform is then placed into the mold, the mold is closed, and the monomer is injected into it. Once the monomer has had time to react with the catalyst on the fiber preform and polymerize, the completed part is removed from the mold. ApplicationsThis technique can be used in liquid composite molding, such as resin transfer molding (RTM), vacuum-assisted RTM (VARTM), and structural reaction injection molding (SRIM), for parts with end-use applications in: - Aerospace

- Sports

- Recreation

- Marine and Automotive Equipment

- Ballistics Electronics

BenefitsBecause multiple resins and catalysts do not need to be added or mixed before being pumped into the mold, this process: - Simplifies production: This technique provides a simpler process that requires fewer steps for producing polymer matrix composites

- Reduces equipment costs: This technique eliminates the need for complex metering and mixing equipment

- Reduces maintenance costs: The technique reduces the heating and cleaning requirements of the injection equipment

|

This technology is a biologically inspired 3D microvascular networks within composite materials provide damage management and active temperature regulation. ... This technology is a biologically inspired 3D microvascular networks within composite materials provide damage management and active temperature regulation. DetailsA novel fabrication of microvascular structural material. Imagine a responsive material that has the ability to react to physical changes by delivering a functional fluid to vital, often inaccessible areas. In nature, this is accomplished through complex vasculature that transports vital fluids to tissues throughout an organism in order to regulate temperature, deliver nutrients, or begin the healing process. Scientists at the University of Illinois have taken their cue from such biological systems in fabricating a 3-dimensional vascular network within a polymer or polymer composite material that can be filled with virtually any fluid. The process is rapid, scalable and easily integrated into existing manufacturing processes with commercially available precursors. In the materials world, this system has the potential to help create longer lasting, safer and fault tolerant products. Through chemical decomposition of the sacrificial fiber relative to the matrix, the original fiber is removed from the matrix leaving behind a pervasive 3D interconnected network of microchannels that can be filled with a fluid either by using capillary action or by pumping. The choice of fluid can impart functionality to the matrix material such as self-healing, temperature regulation, or imparting visibility to areas where damage occurred through the use of a conspicuous dye. These microvascular composite materials can distribute these active fluids for reactions within the matrix in areas that are normally problematic to reach within components. The sacrificial fibers can be handled simultaneously with reinforcing fibers and decompose upon exposure to an external trigger such as processing temperature. This novel material system has the potential to restore structural integrity and extend the safety, reliability and operating life of countless components that are used everyday in numerous industry applications. For example, composite materials play an integral role in everything from aerospace and automotive applications to building materials and must maintain their integrity after repeated thermo-mechanical loading. Under such conditions, micro-cracks can develop over time within the structure significantly weakening its strength. Incorporation of a self-healing capability within the composite can instantly and permanently repair the damage, allowing the composite to retain its structural and mechanical integrity and prolonging its operational life. Figure 1: Creation of 3-D microvascular network. (A) 3-D woven preform, (B) integration of sacrifical fibers, (C) Resin infusion, (D) 3D woven composite and (E) formation of 3-D microvascular network. ApplicationsThis novel material system has the potential to restore structural integrity and extend the safety, reliability and operating life of countless components that are used everyday in numerous industry applications. Composite materials play an integral role in everything from aerospace and automotive applications to building materials and must maintain their integrity after repeated thermo-mechanical loading. Under such conditions, micro-cracks can develop over time within the structure significantly weakening its strength. Incorporation of a self-healing capability within the composite can instantly and permanently repair the damage, allowing the composite to retain its structural and mechanical integrity and prolonging its operational life. Rubber and latex industries could use this material to make improvements to existing products making them safer and longer-lasting. A self-healing tire would significantly increase safety on the road as well as reduce replacement costs. A self healing hose in air brakes for trains and trucks would significantly diminish the catastrophic risk of a failure to the brake system. Latex gloves are the primary barrier between a caregiver and possible infectious agents and tears and puncture can happen without the wearers knowledge. Using this microvascular material filled with a conspicuous dye would alert the wearer of a tear sooner. Alternatively, an anti-infective agent could be used and in the event of a tear or puncture, this agent would be released and help prevent infection. Although lithium ion batteries are gaining attention for use in automotive applications, their performance suffers at high temperatures, which are associated with quicker discharge and safety hazards. They must come with sophisticated battery management systems to maintain the proper temperatures in cars. Battery pack housing would benefit from the incorporation of a 3D microvascular material containing a temperature regulating fluid within the capillaries dissipating heat from hot spots and helping to maintain the proper thermal conditions for optimal battery life. Similarly, as computer technology moves to high-density storage and ultra-fast processing, thermal management becomes an issue. By integrating a microvascular material with a liquid capable of absorbing heat, one could create an effective and compact thermal management system for high density computational applications. BenefitsProvides 3-D microvascular network for self-healing or active temperature regulation Process is scalable and can be woven into large mats All components of process are commercially available

|

Researchers from the University of Illinois have developed a new method for making sacrificial fibers. This method can be used to produce larger and more complex... Researchers from the University of Illinois have developed a new method for making sacrificial fibers. This method can be used to produce larger and more complex microvascular networks in polymers and fiber-reinforced composites. The better mixing method means that the networks left will be more uniform. These microvascular networks are useful for cooling, self-healing applications, or for weight saving designs. |

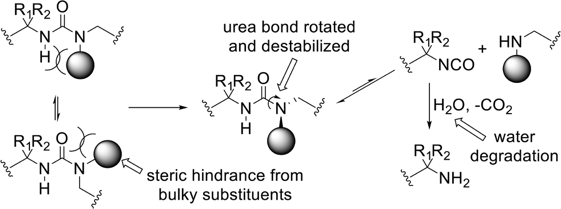

Researchers at the University of Illinois at Urbana-Champaign have developed a powerful new platform of polyureas that enable systems that are hydrolyzable, self-healing,... Researchers at the University of Illinois at Urbana-Champaign have developed a powerful new platform of polyureas that enable systems that are hydrolyzable, self-healing, and malleable, opening exciting applications in the packaging, coating, and adhesives industries. In this new class of polyureas, a bulky substituent is attached to one of the nitrogen atoms of the urea bond and destabilizes the typically stable linkage leading to dynamic dissociation. The polymers can be built from the vast library of isocyanate monomers already developed for the polyurea and polyurethane industries, yielding a wide range of materials with varying, engineered characteristics. Hydrolyzable Polyureas (TF14085) Hydrolyzable polymers are currently used in the agriculture and food industries as environmentally friendly plastics and packaging materials and in the biomedical field as drug delivery systems, surgical sutures, and scaffolds for tissue engineering. However, most hydrolyzable polymers, based on polyester materials or materials containing anhydride, acetal, ketal, or imine linkages, are synthesized via condensation or ring-opening polymerizations, often requiring high temperature conditions and catalysts and resulting in by-products. In contrast, because polyureas are made via a simple and clean chemistry without catalysts or by-products, hydrolyzable polyureas offer users the ability to tune polymer systems to specific applications without involving complex chemistries. In this platform of polyureas, the destabilization introduced by the bulky substituent on the nitrogen of the urea bond leads to dynamic dissociation to the corresponding amines and isocyanates, with the isocyanates further undergoing irreversible hydrolysis in aqueous solution and complete degradation of the polyurea. These degradable polymers are easily synthesized by reacting multifunctional bulky amines with isocyanates and exhibit tunable degradation kinetics. Hydrolyzable Polyureas Bearing Hindered Urea BondsHanze Ying and Jianjun Cheng Journal of American Chemical Society 2014 136 (49), 16974-16977 Polyureas That Love to Break Down

Chemical and Engineering News, December 8, 2014, http://cen.acs.org/articles/92/i49/Polyureas-Love-Break-Down.html

Self-Healing Polyureas (TF12136)

Incorporating the appropriate bulky substituents into polyureas enables polymers that can undergo autonomous, catalyst-free repair at room/low temperatures without the use of microcapsule healing agents, special precursors or customized laboratory/environmental conditions. Commercially available materials are used to produce self-healing polymers with capabilities to re-heal multiple times. Here the bulky substituents are chosen so that (i) the dissociation and reverse (polymer-forming) reactions are rapid and (ii) the polymer-forming reaction is highly favored, thereby insuring optimum bulk mechanical properties of the polymer. Conventional polyureas and poly(urethane-urea)s can thus readily be made dynamic and self-healing while maintaining their stability by replacing regular amines with amines containing bulky substituents. By tuning the substituent, the dynamic properties of the polymer and its mechanical properties can be controlled.

Dynamic Urea Bond for the Design of Reversible and Self-Healing PolymersHanze Ying, Yanfeng Zhang, and Jianjun Cheng Nature Communications 2014 5:3218 doi: 10.1038/ncomms4218 Also see .

Malleable Polyureas (TF15006 / 2015-152) The polyurea systems can also be made malleable and recyclable by exploiting the reversible nature of the urea bond with the bulky subsituent. The cross-linked systems bearing the bulky substituents can be ground into powders and pressed/molded as shown below. The polyurea systems can also be recycled as shown below. |

Researchers at the University of Illinois have developed a new design for manufacturing stretchable batteries with "self-similar serpentine interconnects" that... Researchers at the University of Illinois have developed a new design for manufacturing stretchable batteries with "self-similar serpentine interconnects" that offers extraodinary stretchability along with high recharging capacity. In addition, their design also includes stretchable inductive coils that allows wireless recharging without any direct physical contact. These batteries will be useful for powering wearble and epidermal electronics, a new class of electronic and optoelectronic technology. This technology was developed in the laboratory of Dr. John Rogers, who has received international recognition for his work on bio-integrated electronics. |

This invention is a class of low-power smart antennas, operating at millimeter and microwave frequencies, which are controlled by electronically manipulating the... This invention is a class of low-power smart antennas, operating at millimeter and microwave frequencies, which are controlled by electronically manipulating the direction of an antenna's signal using solid-state technology. These smart antennas are fully compatible with the existing wireless technology, as well as next generation wireless antenna arrays. DetailsThis class of reconfigurable antennas consists of three similar antenna designs, each with its own benefits. The antenna types benefit from compact size and low power consumption, the main difference between the antennas being the geometry of the parasitic array and the method for switching microstrip polarity. How it works The three variations each have three equal spaced parallel strips printed on a grounded dielectric substrate. The center strip is driven with an SMA probe feed, and the linerally polarized antenna is matched by moving the probe location along the x-axis of the center strip. The two outer strips are parasitic and each of them contains one load in the center. When the switches are activated, or the varactors tuned, the effective electrical length of the parasitic strip changes and it alters the induced current on the parasitic strip, changing the antenna's effective radiation pattern up to +35. Applications- Home/Office networking and Wi-Fi: Wireless LANs and WANs will benefit from increased range with fewer dropped connections and faster connection speeds, while users of related technologies like wireless voice over internet protocol (VoIP) would enjoy greater mobility and signal clarity.

- Bluetooth and other M2M systems: MIMO antenna arrays will be the backbone of countless machine-to-machine devices that rely on intercommunication in order to function. This algorithm would decrease the size of such devices while ensuring continued reliability.

- Handheld devices: The market demands connectivity in handheld electronics. Portable gaming devices, for instance, require access to community forums, and pocket PCs are equipped with internet browsers and multimedia software to communicate with desktop computers and wireless routers.

- GPS systems: A constant signal is imperative for high-accuracy GPS devices. This suite of improved antenna technologies could provide for the incorporation of GPS systems into a range of portable devices, which are currently inhibited by size, power, or portability.

- Cellular communications: These technologies will boost cell phone signal and range, while simultaneously minimizing power consumption and miniaturizing device size.

- Large or phased arrays of smart antennas: Antennas can be constructed on a large scale to improve long distance communication in cell phone broadcast towers and government/military base stations.

Benefits- Increase Signal to Noise Ratio: By scanning and switching the antenna's radiation pattern, the antenna system can both circumvent noise and suppress multiple path interference while maintaining communication over a single frequency.

- Compact size: Typically, pattern reconfigurability is achieved by using phased arrays. Phased arrays are too large for use in size-sensitive applications such as consumer electronics devices. This antenna's conformal/ planar design is ideally suited for use in these small applications.

- Elegant Control System: Employing a design of two or four switches, this out-of-phase antenna array consumes minimal power and has negligible computing requirements.

|

A wireless communication device includes multiple antennas spaced apart from each other. Also included is a dielectric substrate with electrically conductive... A wireless communication device includes multiple antennas spaced apart from each other. Also included is a dielectric substrate with electrically conductive ground areas along the substrate opposite the antennas. Signal coupling is decreased between the antennas by connecting the ground areas together with an isolation structure. In one nonlimiting form, this structure includes an electrically conductive meander line structure. |

Dr. Kim from the University of Illinois has developed a 2-part dry adhesive which has an electrically conductive layer and an adhesive layer. The electrically... Dr. Kim from the University of Illinois has developed a 2-part dry adhesive which has an electrically conductive layer and an adhesive layer. The electrically conductive layer is made from carbon black and shape memory polymer (SMP), while the adhesive layer is made of SMP. Applying voltage to the adhesive strips allows the SMP to bond to both curved and flat surfaces. Re-application of voltage allows the adhesive to be removed. This technology represents improvements over current dry adhesives because of the internal heating capability, reversibility of shape before and after bonding and reusability. |

The combination of a unique series-input parallel-output (SIPO) circuit configuration and a sensorless current mode (SCM) technique ensures automatic and nearly perfect... The combination of a unique series-input parallel-output (SIPO) circuit configuration and a sensorless current mode (SCM) technique ensures automatic and nearly perfect load sharing of multiple dc:dc converters even during fast dynamic changes. A power supply in an embodiment of the invention includes a plurality of dc--dc switching power converters, each of which has its input isolated from its output. The power converters are arranged with their respective inputs being series connected and their respective outputs being parallel connected in an embodiment of the invention. In another embodiment of the inputs are parallel connected and the outputs series connected. Each power converter includes an input filter in each of said dc--dc switching power converters and an output filter. Each power converter includes a sensorless current mode control circuit controlling its switching duty ratio. To license the entire Solar Panels portfolio, click here . |

A method for accomplishing energy changes for a power converter to minimize an impact of a disturbance. The power converter includes energy storage and switches.... A method for accomplishing energy changes for a power converter to minimize an impact of a disturbance. The power converter includes energy storage and switches. The method comprises determining a nature of the disturbance, evaluating an amount of energy to be added or removed from the internal storage, and computing operating times of the switches to minimize the impact of the disturbance on outputs of the power converter. |

Researchers from the University of Illinois have developed a technology that enables ultra high bandwidth data communication as well as power transfer over short... Researchers from the University of Illinois have developed a technology that enables ultra high bandwidth data communication as well as power transfer over short distances using acoustic signal.The technology works when items are not touching, it works without pins that could bend or break, it works when moving around and only "near' connected. This technology can be used in any media which allows acoustic waves such as underwater in deep ocean, human-tissue, etc. to achieve data rates in excess of 300Mbps. |

This technology is a method to eliminate voltage overshoot in cables used to connect AC electric motors and pulse width modulation (PWM) inverters. As a function... This technology is a method to eliminate voltage overshoot in cables used to connect AC electric motors and pulse width modulation (PWM) inverters. As a function of cable length and voltage rise time, voltage overshoot occurs when high frequency currents reflect between the motor and source ends of a cable. University of Illinois researchers have devised a compensator that shapes the output of the PWM inverter in order to eliminate these reflections; the method only requires knowledge of the transmission line characteristic impedance and propagation delay. This technique extends the life of motor insulation and protects voltage-sensitive devices. Voltage overshoot occurs when high frequency currents reflect between the motor and source ends of an electrical cable. Reflective waves of current can build up, causing motor insulation failure as well as damage to voltage-sensitive devices. While there have been techniques developed to compensate for voltage overshoot, many are complex, need load characteristics, and often require the use of bulky and expensive equipment. The University of Illinois technique provides a mathematically exact solution that modifies the output of the PWM inverter in order to eliminate wave reflection. This technique is designed to eliminate voltage overshoot in the cable that connects alternating current (AC) electric motors to pulse width modulation (PWM) inverters that use insulated gate bipolar transistors (IGBT). IGBT motor drive cables are particularly susceptible to voltage overshoot due to their extremely fast switching speeds. The compensator, which attaches to either the source or motor end of a cable, is a filter that uses an appropriate linear combination of voltages and currents to transform the transmission line into a pure delay transfer. This prevents wave reflection and thus voltage overshoot. Users do not need to know the motor or drives characteristics; however, they do need to know the transmission line impedance and the propagation delay in order to use this device. This invention improves on existing solutions to voltage overshoot by providing an exact solution rather than approximation. Applications:The range of applications that use AC motors is vast, examples include: - Heavy Industrial Machines or Manufacture: Heavy industries including automotive, materials handling, mining operations, plastic and rubber production, ceramics, textile, and utilities.

- Workshops: Metalworking, printing and woodworking shops.

- Chemical Industries: Chemical refining, pharmaceutical production, and plastic fabrication.

Benefits- Cost-Effective: Eliminates damaging wave reflection, prolonging the usefulness of motors and voltage-sensitive devices.

- Low-Cost and Small: No large or expensive equipment is needed to implement this technology.

- Self-Adapting: Modifies waveform as transmission cable properties change over time.

- Versatile: Can be implemented at either the motor or source side of a cable, allowing users to select the side that is easier to maintain.

|

| Rapid, predictable curing of composites | |

Professors Jeffrey Moore, Nancy Sotos, and Scott White from the University of Illinois has developed a novel method to create composites that allows for much easier... Professors Jeffrey Moore, Nancy Sotos, and Scott White from the University of Illinois has developed a novel method to create composites that allows for much easier manufacturing and more design latitude. |

Dr. Moore from the University of Illinois has developed a new method of 3D printing which enables the use of high quality components. This printing method cures materials... Dr. Moore from the University of Illinois has developed a new method of 3D printing which enables the use of high quality components. This printing method cures materials as they print and removes the need for additional processing steps.

This invention could be used to make 3D printed composite materials. It expands the applications of 3D printing. |

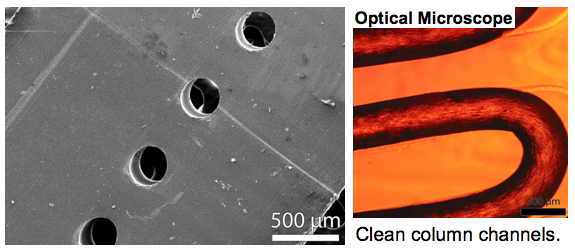

Dr. Suslick has developed a method to form polymer microcolumns for portable and disposable gas chromatography. Using sacrificial materials as a template, 2D and 3D... Dr. Suslick has developed a method to form polymer microcolumns for portable and disposable gas chromatography. Using sacrificial materials as a template, 2D and 3D microcolumns are formed to separate volatile chemicals.

This method is cost effective and easy to implement.

|

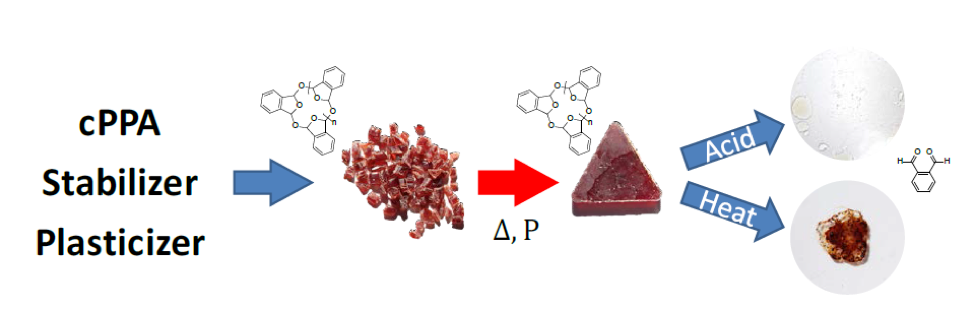

Dr. Moore from the University of Illinois at Urbana-Champaign has developed a method for enhancing the thermal stability of cyclic poly(phthalaldehyde) (“cPPA”). cPPA is a... Dr. Moore from the University of Illinois at Urbana-Champaign has developed a method for enhancing the thermal stability of cyclic poly(phthalaldehyde) (“cPPA”). cPPA is a transient material which is capable of depolymerizing in response to a stimulus (e.g., acid, heat). Until now, the low degradation temperature of cPPA has precluded thermal processing of the material. Additionally, cPPA’s unpredictable stability and thermal degradation behavior prevented standardization. The inventors identified a method for stabilizing cPPA to enable thermal processing of the material. Thermal processing allows more complex architectures to be fabricated from cPPA, these architectures can then undergo triggered depolymerization to break down the material. Potential applications for this material include disappearing drones and lithography.

|

Dr. Yongqi Lu from ISGS has developed a novel biphasic system that can be used for the capture of CO2 in a much more cost effective way. This system uses an organic... Dr. Yongqi Lu from ISGS has developed a novel biphasic system that can be used for the capture of CO2 in a much more cost effective way. This system uses an organic compound for phase regulation. Since phase regulation is not dependent on the amine component, this solvent system is much more efficient for biphasic separation of CO2. |

| Method for Delaying Frost Growth on Heat Exchangers | |

A meniscus-guided solution coating technique to produce pharmaceutical nanothin films. This is a new way to manufacture personalized multilayer combination drugs, which can be beneficial to types of cancer where mono-chemotherapy is ineffective. This new technology enables a uniform deposition of thin films down to a few nm in thickness, easy alternation of the film morphology (modulation of dissolution rate) and polymorphism (control of bioavailability), and a layer-by-layer production of dosages comprised of multiple active pharmaceutical ingredients. The method is cost-competitive, scalable, and high-throughput.

|

|

Dr. Tawfick from the University of IL has developed a composition of carbon fiber and silicone to create an artificial coiled muscle. This particular composition gives... Dr. Tawfick from the University of IL has developed a composition of carbon fiber and silicone to create an artificial coiled muscle. This particular composition gives the artificial muscle the ability to lift 12,600 times its own weight when an electrical current is applied to it. This invention could help replace bulky actuators and could be useful in prosthetics as well as other industries. Publications – C Lamuta, S. Tawfick, S. Messelot, Theory of the Tensile Actuation of Fiber Reinforced Coiled Muscles, Smart Materials and Structures, (Apr. 20, 2018). |

Dr. Sottos from the University of IL has developed a method of creating microscopic channels within a gel matrix. The process takes less time... Dr. Sottos from the University of IL has developed a method of creating microscopic channels within a gel matrix. The process takes less time then conventional methods and operates are temperatures below 180ºC. The invention can be used for transporting fluids for various biological uses. This invention could be used for various medical purposes. |

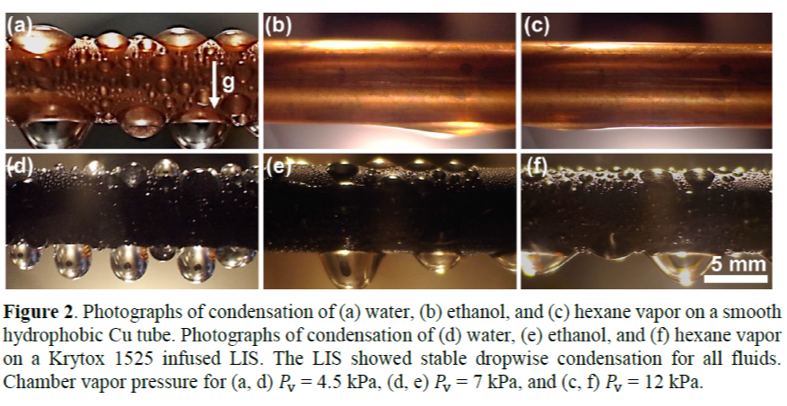

Dr. Nenad Miljkovic from University of Illinois has developed an invention which improves the condensation of organic fluids. Vapor condensation is an ubiquitous process... Dr. Nenad Miljkovic from University of Illinois has developed an invention which improves the condensation of organic fluids. Vapor condensation is an ubiquitous process applied in a wide range of industrial processes including power generation, distillation, air conditioning and refrigeration systems and natural gas processing. Over the past several decades, water-repellent or hydrophobic surfaces have been developed for water condensation. However, this approach does not work with low-surface-tension fluids such as alcohols and hydrocarbons. Other approaches, such as omniphobic surfaces, fail for condensation applications. Starting from regular metal tubes (e.g. copper), Dr. Miljkovic and coworkers developed scalable nanostructured lubricant infused surfaces (LIS) that can sustain rigorous condensation conditions.

|

Dr. Zimmerman from the University of Illinois has developed a new class of compounds for the fabrication of repurposable polyurethane materials. The polyurethanes made... Dr. Zimmerman from the University of Illinois has developed a new class of compounds for the fabrication of repurposable polyurethane materials. The polyurethanes made from these compounds can be decomposed, under mild conditions, to useful alternative compounds and reused as adhesives with superior strength. Additionally, the polyurethanes made from these compounds exhibit nearly identical properties to those currently used in industry and are vitrimers that can self-heal. BenefitThis invention minimizes the waste associated with the production and use of polyurethanes. ApplicationPrimary use is fabrication of polyurethane elastomers and foams for a variety of industrially relevant applications. These relevant applications include manufacture of high-resilience foam seating, rigid foam insulation panels, microcellular foam seals and gaskets, durable elastomeric wheels and tires, automotive suspension bushings, electrical potting compounds, high-performance adhesives, surface coatings and surface sealants, synthetic fibers, carpet underlay, hard-plastic parts, condoms, and hoses. |

| Coating for Anti-fouling and Anti-corrosion on Metals | |

Dr. Nenad Miljkovic’s research group has developed a new technology to reduce the susceptibility of metallic surfaces to fouling/scaling. The invention is a thin (<~100... Dr. Nenad Miljkovic’s research group has developed a new technology to reduce the susceptibility of metallic surfaces to fouling/scaling. The invention is a thin (<~100 nm) multi-layered solid-state coating that reduces the surface energy and nucleation site density of metals such as aluminum, copper, and more. The technology has been demonstrated to reduce scale accumulation by 95% as compared to uncoated surfaces and eliminates the intrinsic durability issues of oil-based coatings. Applications for the technology include the reduction of scale build-up on air conditioning and refrigeration systems and the prevention of coke deposition for aviation applications. |

Researchers from the University of Illinois have developed a new technique for fabricating elastomeric materials, namely 1,4-polybutadiene and co-polymers of 1,4-... Researchers from the University of Illinois have developed a new technique for fabricating elastomeric materials, namely 1,4-polybutadiene and co-polymers of 1,4-polybutadiene. The technique employs frontal ring-opening metathesis polymerization allowing for a rapid and energy efficient means of producing these materials. The materials produced by this technique may be used to fabricate a variety of products including tires, tubes, belts, gaskets, etc. This technology also allows for the rapid fabrication of elastomeric materials with shape memory properties.

|

Dr. Damien Guironnet from the University of Illinois has developed a chemical recycling method for upcycling propylene and isobutene solid wastes. This technique may be... Dr. Damien Guironnet from the University of Illinois has developed a chemical recycling method for upcycling propylene and isobutene solid wastes. This technique may be used to produce higher value feedstock materials (e.g., propylene and isobutene) from polyethylene and polypropylene with high selectivity. This process achieves high yield, in comparison with other chemical recycling techniques, through a combination of reactor design, catalyst selection, and process optimization. |

Dr. Seok Kim has developed a robotic gripper arm which has potential applications in many fields including aerospace, electronics, manufacturing, logistics, and micro-... Dr. Seok Kim has developed a robotic gripper arm which has potential applications in many fields including aerospace, electronics, manufacturing, logistics, and micro-electromechanical systems industries. This invention improves on current technology because it has unique properties that can pick-and-place interacting only a single surface of a target object, work in a vacuum or porous surface objects and that can be cheaply and simply manufactured. This design includes improvements to the adhesive's detachment capabilities.

|

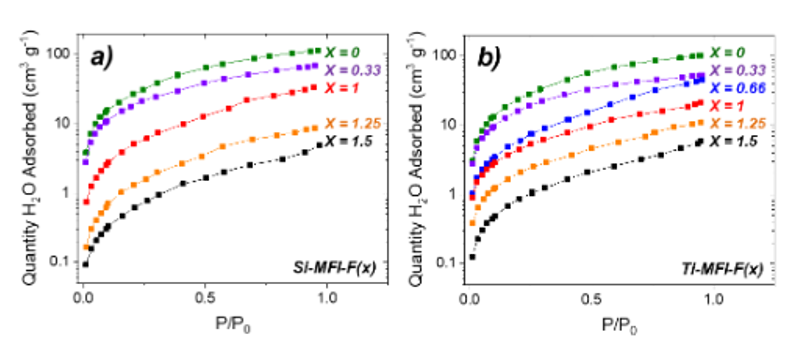

Dr. Flaherty has developed a method for synthesizing zeolites with controlled defect density. By controlling the defect density of the zeolite materials during synthesis,... Dr. Flaherty has developed a method for synthesizing zeolites with controlled defect density. By controlling the defect density of the zeolite materials during synthesis, their hydrophobicity can be controlled. This is a first of its kind synthetic technique allows for the physical and chemical properties of a variety of zeolite materials to be finely tuned which may have a significant impact on their performance as catalysts and adsorbents. Moreover, this synthetic technique can be easily implemented into existing process streams with minor or no modifications to existing procedures.

|

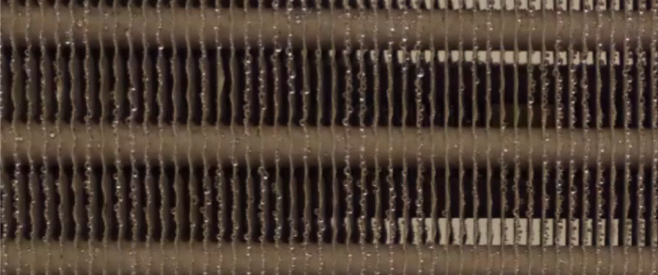

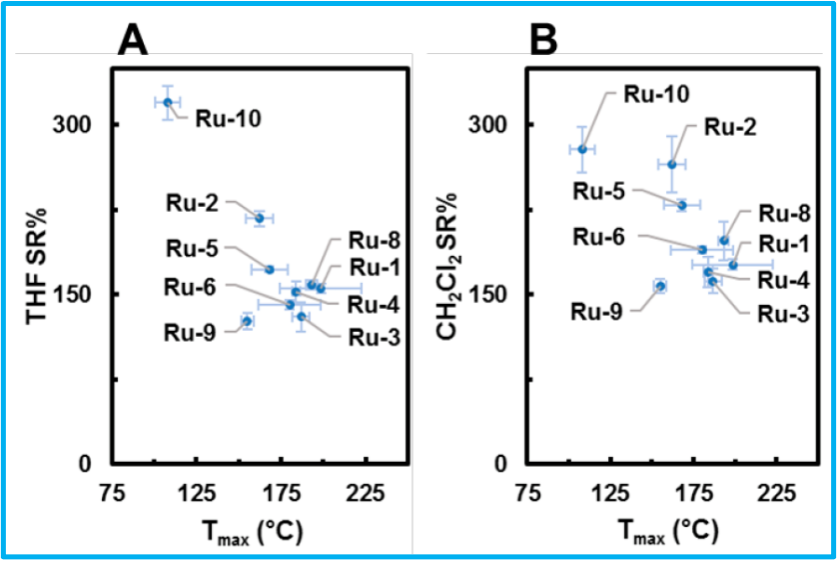

Researchers at Illinois have developed new catalytic systems to perform FROMP. Large-scale, energy efficient industrial polymerization syntheses are accessed with FROMP.... Researchers at Illinois have developed new catalytic systems to perform FROMP. Large-scale, energy efficient industrial polymerization syntheses are accessed with FROMP. So far, 2nd generation Grubbs catalyst has been extensively used for FROMP. Exploring new catalyst formulations resulted in polymers with varied mechanical properties and affected the polymerization process. These new formulations expand on previously developed synthesis to offer greater flexibility, tunability, and control of end products and the manufacturing process. Benefits:- Energy efficient

- Short reaction times

- Resultant polymers with different mechanical properties

- Unusually flexible polymer

Market Application: - Varied applications including chlor-alkali production, automotive, construction industries

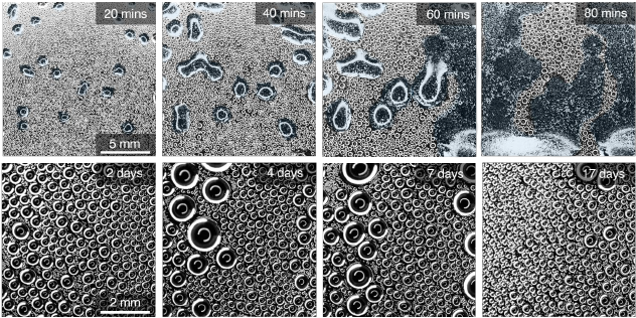

Image shows swelling behavior of the resultant polymersusing new catalyst formulations. |

Dr. Miljkovic has developed microstructured aluminum (Al) tubes with increased heat transfer rates of 240% during refrigerant flow boiling. Highly conformal are generated... Dr. Miljkovic has developed microstructured aluminum (Al) tubes with increased heat transfer rates of 240% during refrigerant flow boiling. Highly conformal are generated by a scalable etching technique. The cost-effective techniques used to create etched-Al microstructures stand to significantly reduce manufacturing cost and time required for current enhancement approaches such as extrusion, drawing, and welding. At the same time increased performance is ensured on the thermal side. In addition, the fabricated etched structures are highly durable due to structure formation based on the base metal, and therefore do not suffer from thermal expansion coefficient mismatch issues, as is the case with other enhancements. |

Professor Xiao Su and colleagues have developed an electrochemical system for the separation and reutilization of homogenous catalysts including Pt and Pd-cross coupling... Professor Xiao Su and colleagues have developed an electrochemical system for the separation and reutilization of homogenous catalysts including Pt and Pd-cross coupling catalysts and many other noble metal homogenous catalysts. This catalyst recycling system allows for the direct capture of a homogenous catalysts from a reaction mixture, the captured catalyst can then be desorbed into a new reaction mixture. Notably, this catalyst capture and release system operates without chemically altering the catalyst species thus this system maintains the original catalyst activity. This electrochemical system utilizes redox polymer electrodes allowing for the >99% catalyst adsorption within a 5-minute period. The adsorption properties of this system can be easily adjusted by modifying the applied current and electrode dimensions. Furthermore, >99% of the catalyst adsorbed can be released from the redox electrodes resulting in a highly efficient catalyst recycling system. |

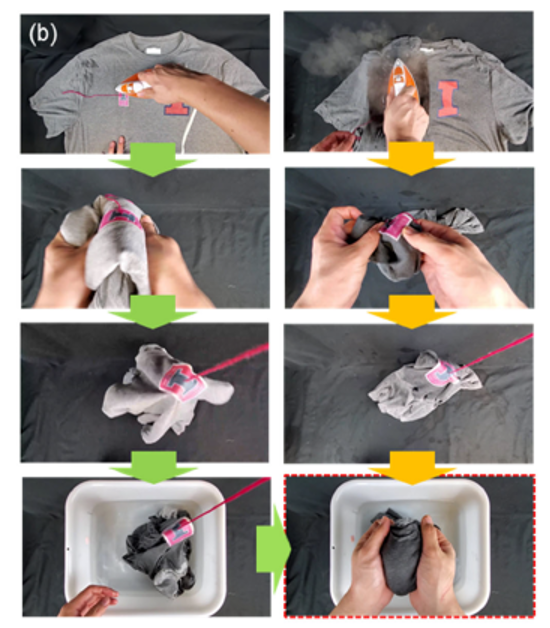

Researchers have developed a dry surface and shape adaptive thin shape memory polymer adhesive specifically targeting flexible fabric adherends. Current temporary or... Researchers have developed a dry surface and shape adaptive thin shape memory polymer adhesive specifically targeting flexible fabric adherends. Current temporary or permanent adhesives for lightweight fabrics lack reusability, shape and surface adaptability. The invention uses unique characteristics of shape memory polymer to create a surface and shape adaptive adhesive that leaves no residue, can be reused, is washable and has high holding strength. The primary application of this invention will be to use as thin flexible adhesive for fabrics.

|

Dr. Lili Cai and her team at the University of Illinois have developed a new nanoporous composite material for passive cooling applications. This composite has solar... Dr. Lili Cai and her team at the University of Illinois have developed a new nanoporous composite material for passive cooling applications. This composite has solar reflectivity of 96.2%, infrared emissivity greater than 90%, and can generate a cooling power of 85 W/m2 to reduce subambient temperature by up to 6.1°C without any energy inputs. The material is inexpensive, easier to fabricate than state-of-the-art passive cooling materials, and can retain its properties even after thermal processing or 3D printing. |

Kyle Smith has improved current flow channel designs by integrating the flow channel inside of the electrode. This enables his design to improve current electrode... Kyle Smith has improved current flow channel designs by integrating the flow channel inside of the electrode. This enables his design to improve current electrode performance by a factor of 1000. Furthermore, Dr. Smith has improved the shape and arrangement of his flow channels by arranging them in a hierarchical fashion and creating a cube-root shape. This results in an optimized and improved flow channel that makes the electrodes much more permeable than current designs. Effectively, these electrodes can now have a flow with very low amounts of pressure required. |

Hydrophobic coatings are water-resistant and can be used to condense steam for efficient heat-transfer. Certain applications require ultra-thin coating, which the current... Hydrophobic coatings are water-resistant and can be used to condense steam for efficient heat-transfer. Certain applications require ultra-thin coating, which the current coats are prone to delamination upon surface damage. In a collaborative effort between the Evans and Miljkovic lab, a new ultra-thin hydrophobic coating has been developed. This coating can be easily applied to existing materials to protect surfaces against water damage. Unlike previous coatings, this invention is capable of self-heal, thus enhancing its durability and lifetime. Pictured below: top row is previous coatings, bottom row is this invention.

|

Inventors from the University of Illinois have developed a method to form thin film depositions from a variety of sources, using Vacuum UV light. This low... Inventors from the University of Illinois have developed a method to form thin film depositions from a variety of sources, using Vacuum UV light. This low temperature method is fast and allows for a low defect and uniform film deposition on almost any surface. Moreover it is capable of forming films from vapor, solid and liquid precursors. Applications include mioelectronics, optoelectronics, semiconductor surface and metals passivation, coating of materials with low melting point, dielectric materials, and potentially hydraulic rams to prevent oxidation of materials. |